A vertical milling screw reclaimer

A reclaiming device, vertical milling technology, applied in the field of vertical milling screw reclaiming device, can solve the problems of limited ship unloader capacity, small material flow at the inlet, and reduced reclaiming efficiency, so as to reduce energy consumption of vertical conveying , Improve ship unloading capacity and facilitate adjustment and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

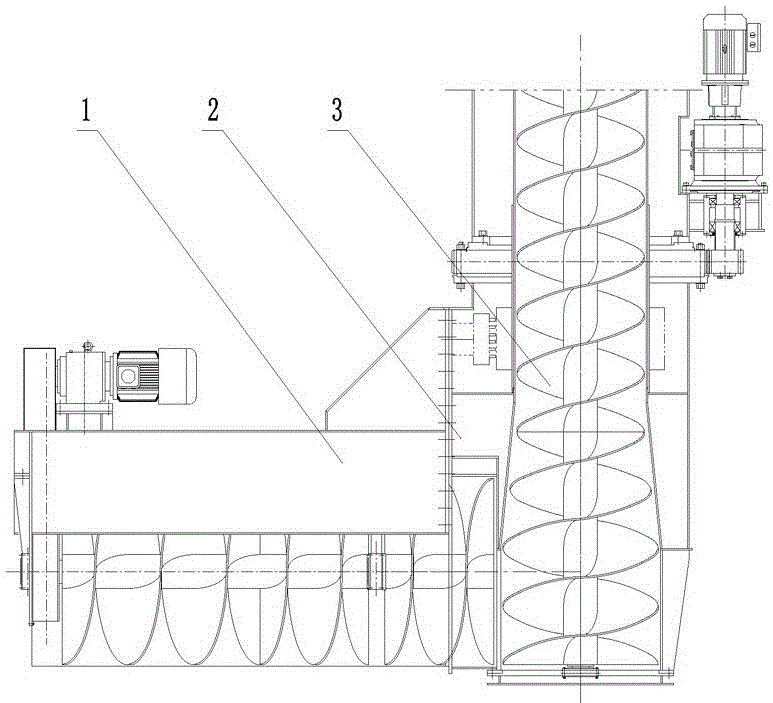

[0028] Such as figure 1 As shown, the vertical milling screw retrieving device includes a horizontal collecting screw mechanism 1, a retrieving rotary mechanism 2 and a vertical screw conveyor 3, the vertical screw conveyor 3 is arranged in the reclaiming rotary mechanism 2, and the vertical screw conveyor 3 The bottom is rotationally connected with the bottom of the reclaiming rotary mechanism 2, and the horizontal collecting screw mechanism 1 passes through the reclaiming rotary mechanism 2 and communicates with the vertical screw conveyor 3.

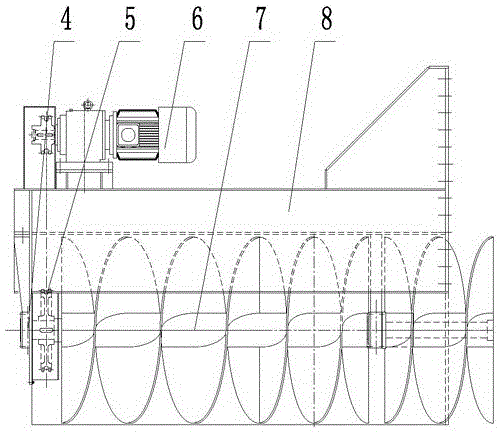

[0029] Such as figure 2 and image 3 As shown, the horizontal collection screw mechanism 1 includes a transmission device 5, a driving device 6, a collection screw 7 and a collection screw support 8, and is far away from the collection screw 7 end of the reclaiming rotary mechanism 2 and the reclaiming rotary mechanism 2 and The end of the collecting screw 7 far away from the reclaiming rotary mechanism 2 is equipped with a thrust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com