Shaver head and assembling method thereof

A technology for razors and blades, which is applied in the field of razor blades and their assembly, which can solve the problems of loose clamping of razor blades, large clip consumables, and increased input costs, etc., to achieve small material consumption and shortened Length requirements, the effect of improving the firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

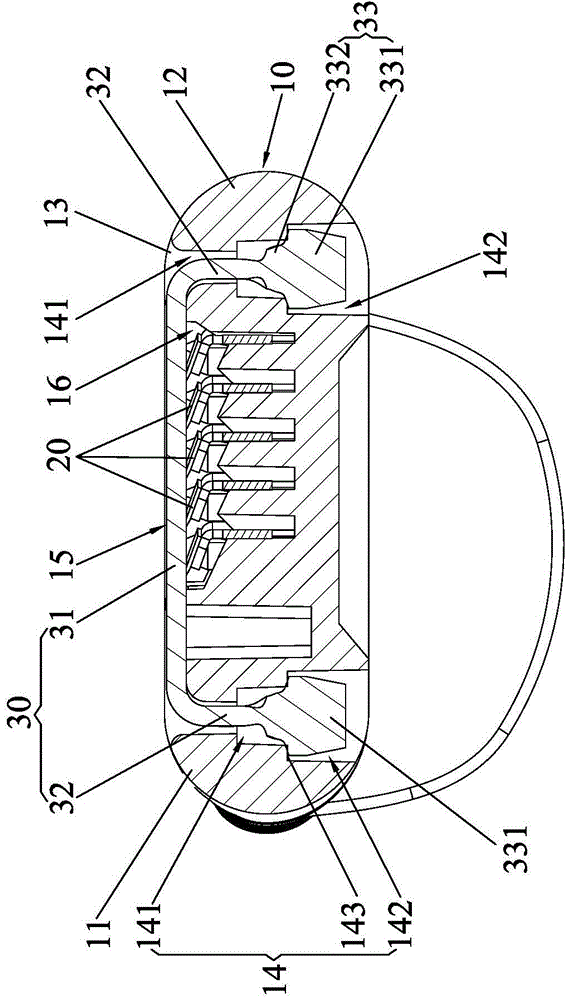

[0032] see Figure 1 to Figure 5 , the razor head 100 of the present invention includes a housing 10 , one or more razor blades 20 and a clip 30 . Specifically, in this embodiment, the number of razor blades 20 is 5, of course, in other embodiments, the number of razor blades 20 can also be 1, 2, 3, 4 or 6, etc., so it is not limited to the above examples.

[0033] like figure 1 , figure 2 and Figure 4 As shown, the housing 10 has a front edge 11, a rear edge 12, a side edge 13 extending between the front edge 11 and the rear edge 12, and a through hole 14 between the front edge 11 and the rear edge 12 (see figure 2 ), preferably, the front edge 11, the rear edge 12 and the side edge 13 jointly enclose a placement space 16 for the razor blade 20 to be pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com