Forming die for locking thread

A technology for forming molds and threads, applied in the field of parts processing molds, can solve the problems of lack of special anti-loosening section thread processing, only ordinary threads can be formed, etc., and achieve the effects of good anti-loosening effect, stable processing performance and simple mold structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

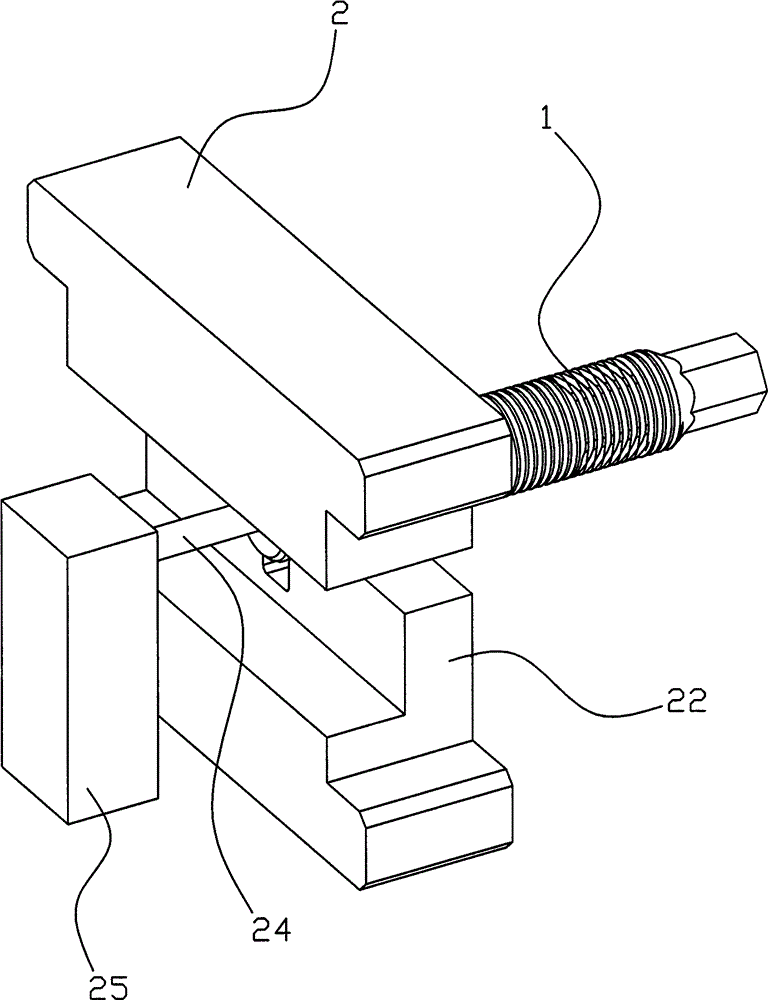

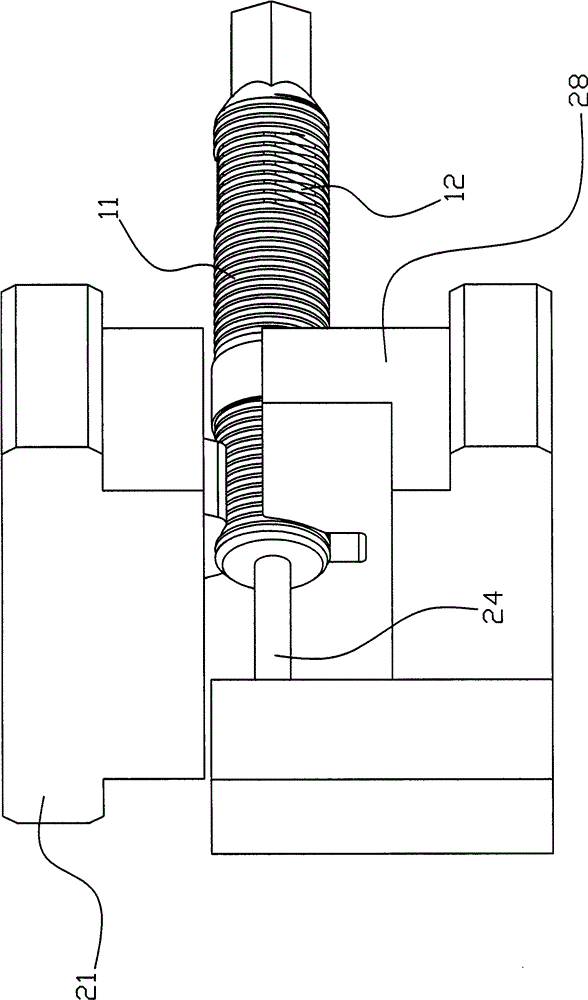

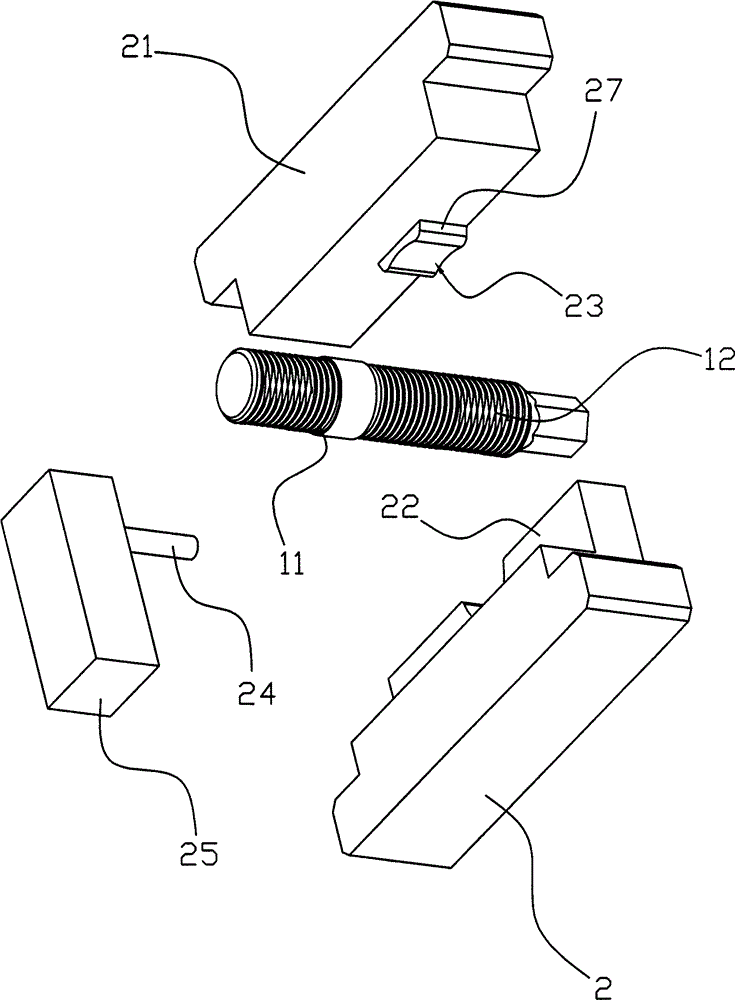

[0023] Such as Figure 1 to Figure 8 As shown, the forming die of the locking thread of the present embodiment includes an upper die 21 and a lower die 22, the upper die 21 can move up and down and be linked with the driving device, and the bottom surface of the upper die 21 is provided with a screw for extruding the screw thread. The arc surface 23 is provided with left and right symmetrical arc surfaces 23 on the left and right sides of the lower mold 22. The arc surface 23 of the upper mold 21 has the same radius as the two sections of arc surfaces 23 on the left and right of the lower mold 22. When the upper mold 21 When moving down and matching with the lower mold 22, the three sections of arcs are located on the same circumferential surface. The arc length of the arc surface 23 of the upper mold and the arc length of the two arc surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com