An Intelligent Architectural Paint Coating Scrub Resistance Tester

A technology of architectural coatings and scrub resistance, applied in the direction of testing wear resistance, etc., can solve the problems of low work efficiency and the influence of human factors on test results, and achieve the effect of scrub resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

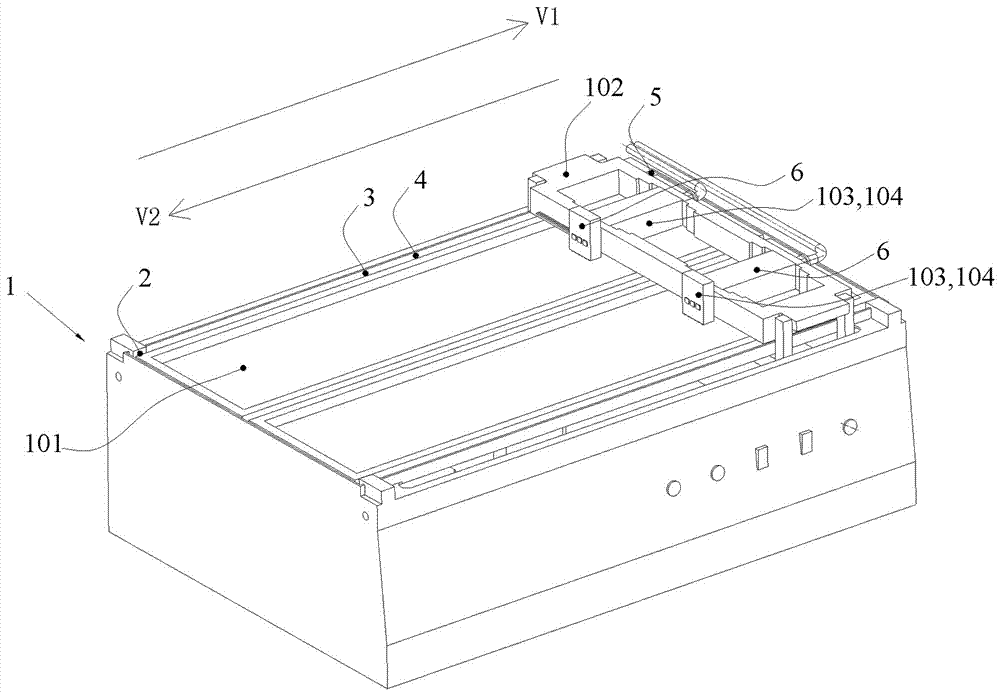

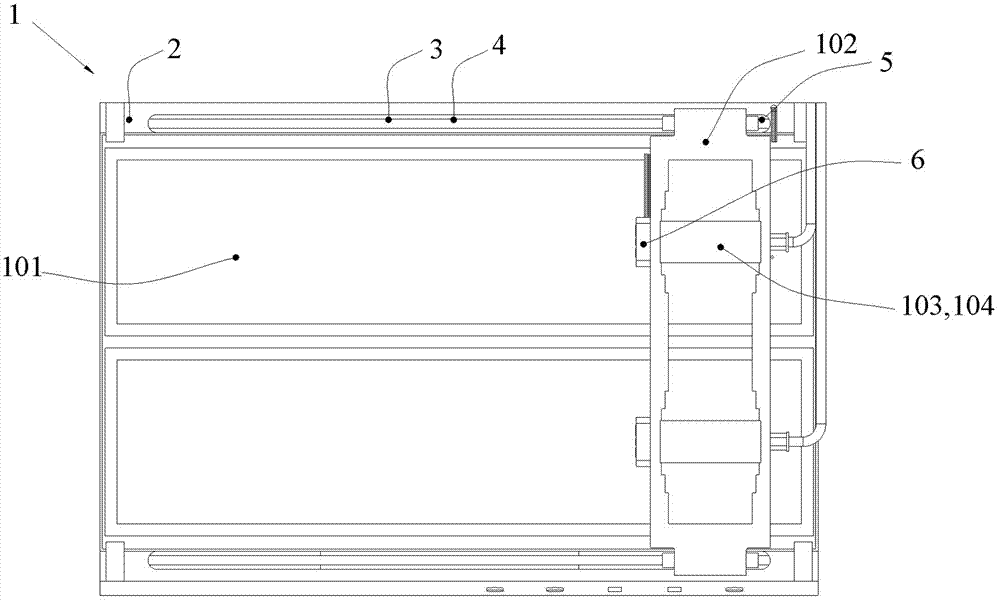

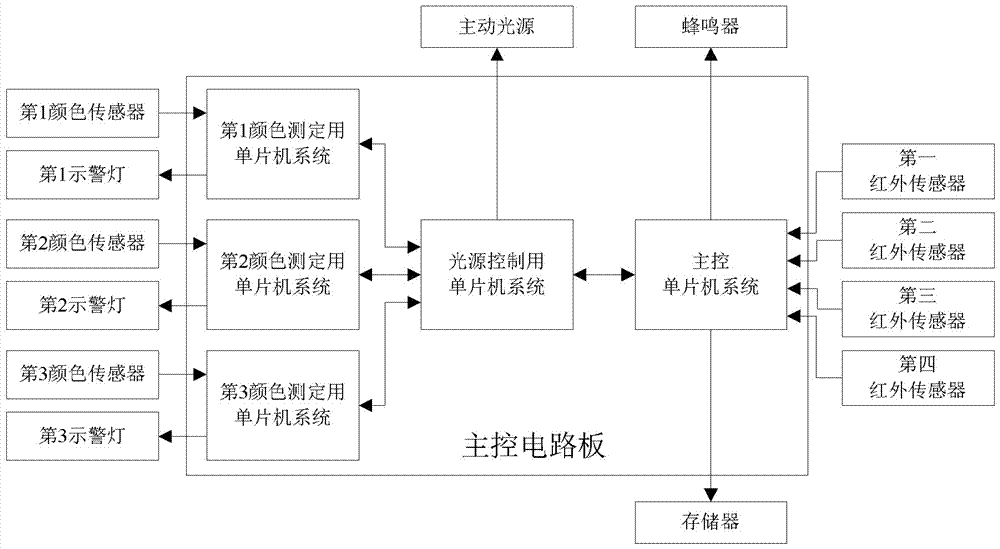

[0024] Such as figure 1 with figure 2 As shown, the intelligent building paint coating scrub resistance tester of the present invention includes a scrub resistance test machine 1, a position detection device, a color scanning head 6 and a counting device.

[0025] The washing resistance test machine 1 is provided with a platform 101, a sliding bracket 102, a brush 103, and a weight 104. The platform 101 is used to support the cement board coated with the tested architectural paint on the top surface. The sliding bracket 102 is located above the platform 101. It can move linearly back and forth between the front and rear ends of the platform 101 under the drive of an electric system (not shown in the figure), and when the sliding bracket 102 moves to the front and rear ends of the platform 101, it is close to static and moves to In the middle section of the platform 101, the speed reaches the highest and is close to a uniform speed. The brush 103 is installed on the sliding suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com