Water curtain type spinning air conditioning system

An air-conditioning system and textile technology, applied in the textile field, can solve the problems of incomplete removal of flying dust and single function, and achieve the effects of not wasting water resources, large area, and maintaining volatile performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

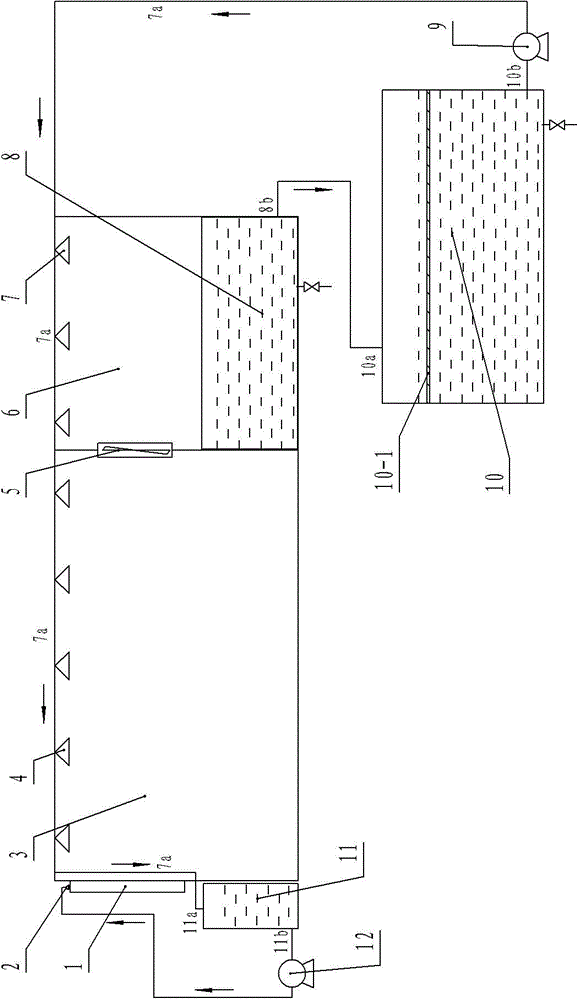

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

[0013] figure 1 The water curtain type textile air-conditioning system shown includes a plurality of exhaust fans 5, and the exhaust fans 5 are installed on the wall on one side of the textile workshop 3. A breathable hanging curtain 1 wetted by the first nozzle 2 respectively, the water inlet of the first nozzle 2 communicates with the water outlet 11b of the water tank 11 through the first pump 12; A plurality of second nozzles 4; the outside of the textile workshop 3 communicates with the air outlet of the exhaust fan 5 with a dust filter chamber 6, the top of the dust filter chamber 6 is provided with a plurality of third nozzles 7 with nozzles downward, and the bottom of the dust filter chamber 6 is provided with A dust suction pool 8, the water outlet 8b of the dust suction pool 8 communicates with the water inlet 10a of a sedimentation tank 10 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com