Assembly-type node of cable strut structure

An assembled node and assembled technology, which is applied in the direction of transmission elements or pulley ropes or cables, textile cables, belts/chains/gears, etc., can solve the problems of complex node structure and inconvenient node processing and manufacture, and achieve reduced construction costs. Convenient maintenance and replacement, convenient construction and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

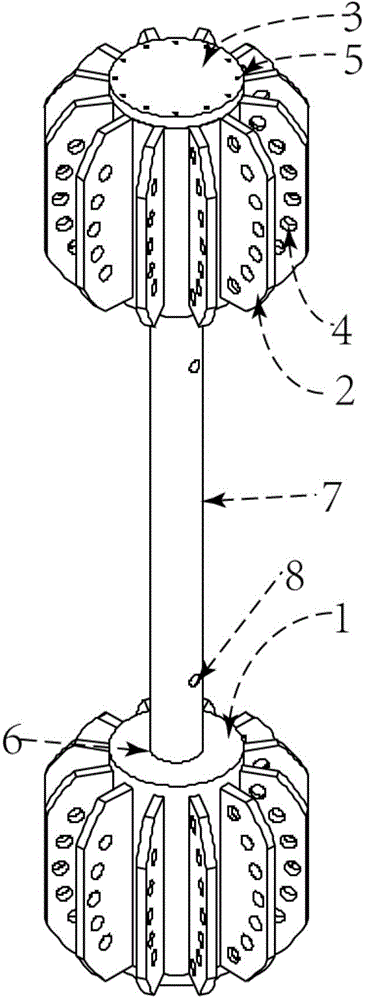

[0028] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing

[0029] The assembled joint of the cable-strut structure of the present invention mainly solves the shortcomings of the traditional joints in the cable-strut tension structure of various types, complex structure, lack of standardization, and inconvenient manufacturing and assembly, so as to simplify the form of the joint on the basis of ensuring the mechanical performance of the joint , so that part of the accessories in the node can be standardized to form an assembleable node.

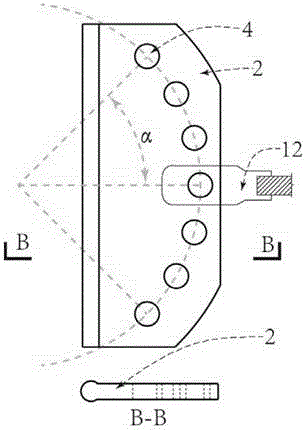

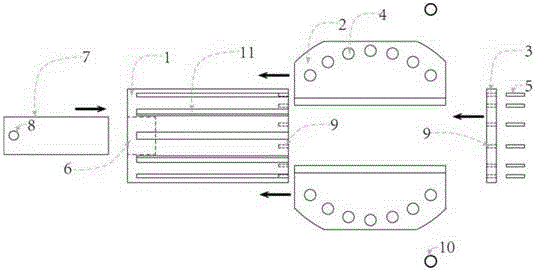

[0030] Such as figure 1 , figure 2 As shown, the assembled node of the cable-strut structure of the present invention is mainly composed of a node center body 1 , an ear plate 2 , a node cover plate 3 , and bolts 5 .

[0031] Such as figure 1 As shown, the prefabricated nodes of the cable-strut structure are respectively connected to both ends of the compression member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com