Coal mine gas drainage pipeline optical fiber monitoring system

A gas drainage and monitoring system technology, applied in gas discharge, mining equipment, mining equipment, etc., can solve problems such as economic loss, low efficiency, waste of valuable resources, etc., to ensure the safety of underground personnel, and ensure real-time and reliability. , to ensure the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

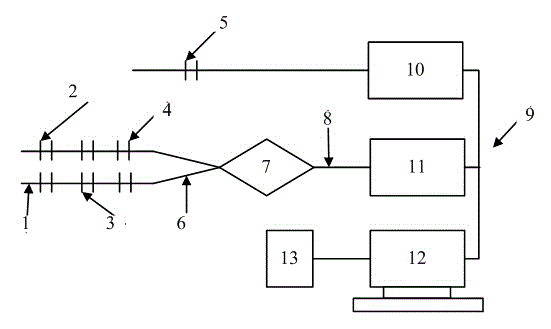

[0018] Such as figure 1 As shown, the optical fiber monitoring system used in gas drainage includes an optical fiber temperature sensor 4, an optical fiber pressure sensor 3, an optical fiber laser gas sensor 5, an optical fiber flow sensor 2, a single-mode optical fiber 6, a coupler 7, a multi-core optical cable 8, The optical fiber grating demodulator 11, the fiber gas gas demodulator 10, and the computer 12 are composed. The optical fiber flow sensor 2, the temperature sensor 4, and the pressure sensor 3 are connected to the coupler 7 through the single-mode optical fiber 6, and the coupler 7 is connected to the fiber grating demodulator 11 through a multi-core optical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com