Rail sleeper and method for mounting nut sleeve

A technology of nut sleeves and sleeper rails, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems of non-environmental protection, low carbon, strength not reaching light pillows, and not being widely used, so as to save maintenance and protect The cost and environmental damage are small, and the integrity and cross-sectional shape are consistent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

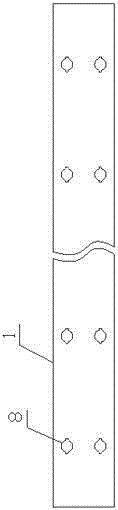

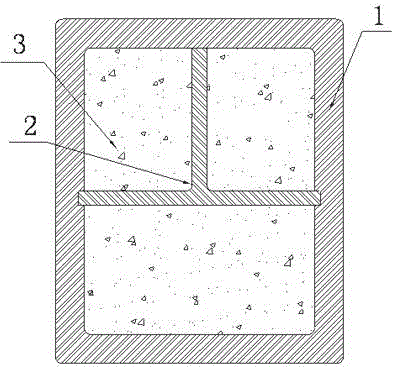

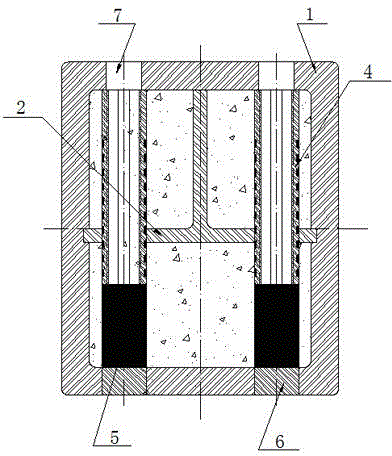

[0038] A method for installing a nut sleeve on a sleeper rail, comprising the following steps: firstly drill down from the upper surface of a sleeper body 1 a bolt hole 7 matching the bolt until the lower surface of the sleeper body 1 (such as figure 2 shown), and then from the lower surface of the sleeper body 1, process the nut sleeve hole matching the shape of the nut sleeve 4 to the bottom plane of the upper surface of the sleeper body; then coat the nut sleeve 4 with epoxy resin 5 glue, and then coat the The nut sleeve 4 of the resin 5 glue is embedded into the sleeper from the lower surface of the sleeper body 1, so that the upper plane of the nut sleeve 4 reaches the bottom plane of the upper surface of the sleeper body 1, so that the bottom plane of the upper surface of the sleeper body 1 acts as a support for the nut. The limit function of the cover 4; then fill the empty hole of the glue storage tank 11 at the lower end of the nut cover 4 with epoxy resin, and then c...

Embodiment 2

[0040] A method for installing a nut sleeve on a sleeper rail, comprising the following steps: firstly, a hole is drilled downward from the upper surface of the sleeper body 1 to the bolt guide rail of the fiber-reinforced resin-based composite material profile 2 of the pillow core, and a ring is cast into the hole 8 Epoxy resin 5, then insert the nut sleeve in the epoxy resin 5, insert the nut sleeve 4 in the hole, and get final product after the epoxy resin 5 is cured.

Embodiment 3

[0042] A method for installing a nut sleeve on a sleeper rail, comprising the following steps: first, the upper surface of the sleeper body 1 is drilled down to the bolt guide rail of the fiber-reinforced resin-based composite material profile of the pillow core, and epoxy resin is poured into the hole 8 5. After the epoxy resin 5 is cured, drill and tap the cured epoxy resin body to obtain the threaded holes for the bolts to be installed; or insert the required screw holes after pouring the epoxy resin 5 into the hole 8. Installed bolts, and the surface is coated with a release agent. After the epoxy resin 5 is cured, loosen the bolts and take them out to obtain the threaded holes for the bolts to be installed (such as Figure 5 shown).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com