A car door gluing and bonding tooling fixture used on an automobile door gluing production line

A technology for automobile doors and tooling fixtures, applied in the field of automated production equipment, can solve problems such as affecting production efficiency, non-uniform force of pressing ribs, and differences in bonding strength and quality, so as to improve work efficiency and reduce human labor. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

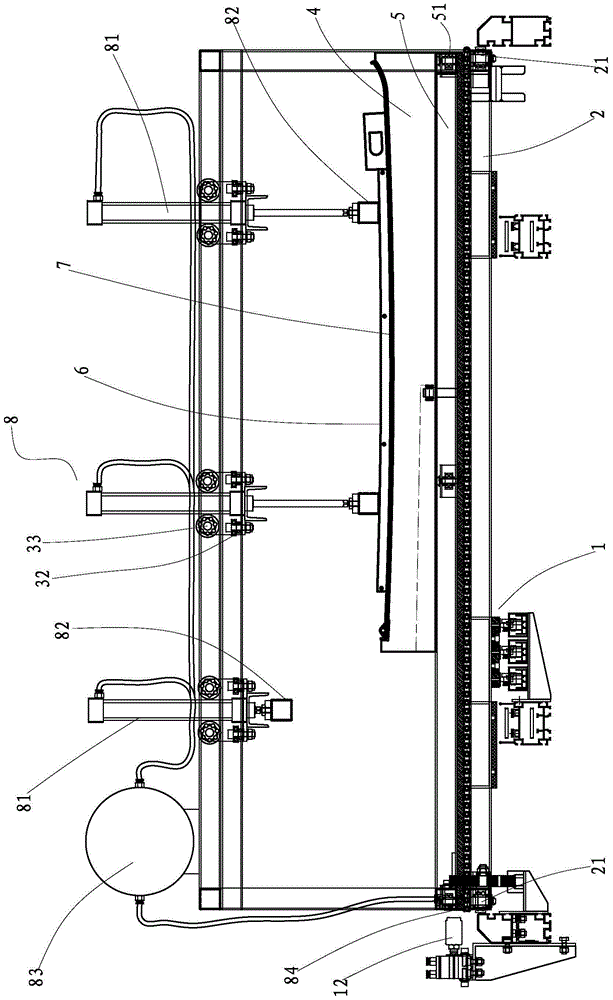

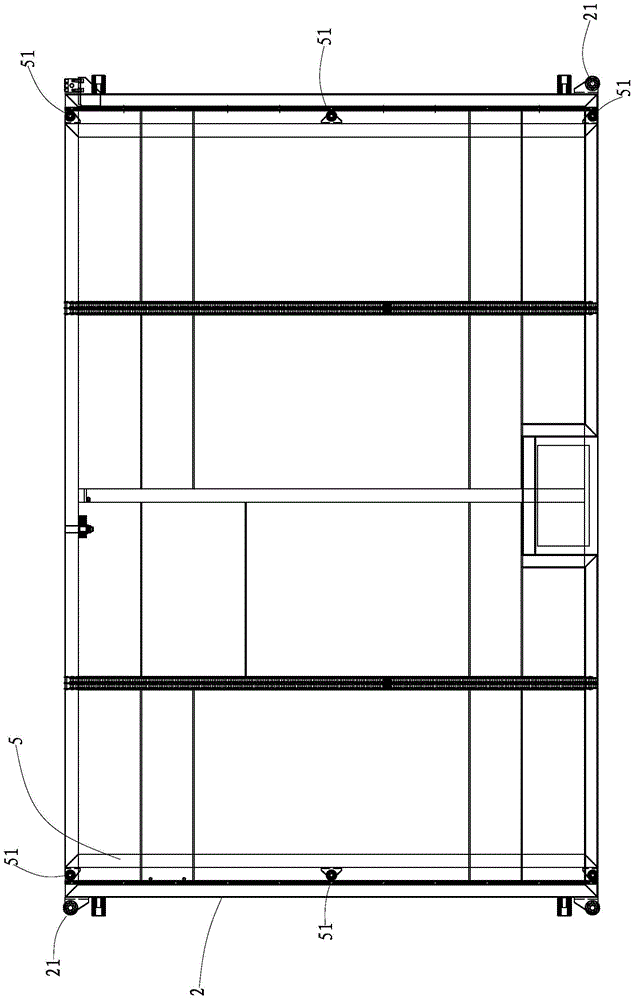

[0028] The present invention is a car door gluing and bonding fixture used on a car door gluing production line. There is a movable seat 5 for supporting the former 4 that can slide relative to the base 2, and the door 7 is attached to the former 4. The support 3 is provided with a rib 6 and a door for pressing and placing on the former 4. 7 Make the rib 6 and the car door 7 keep bonding the pressing mechanism 8 by glue. During the conveying process, the pressing mechanism 8 keeps pressing the rib 6 bonded on the door 7 by glue all the time, and the pressing force remains consistent before and after. Then solidify, that is, the rib 6 is firmly bonded on the door 7. Realized that when the rib 6 and the car door 7 are glued together, they can be automatically pressed while conveying, avoiding the problem of waiting for the dry glue to be conveyed and affecting the production efficiency, so the present invention has the characteristics of improving production efficiency.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com