Intensive power unit driving board

A power unit and drive board technology, applied in reactive power adjustment/elimination/compensation, electrical components, AC network circuits, etc., can solve the problem of resonance in the power grid system, which affects the reliable operation of the system, and cannot monitor the IGBT voltage value and current in real time value and its own temperature to meet the requirements of power factor compensation and dynamically adjust reactive power output rapidly and continuously

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

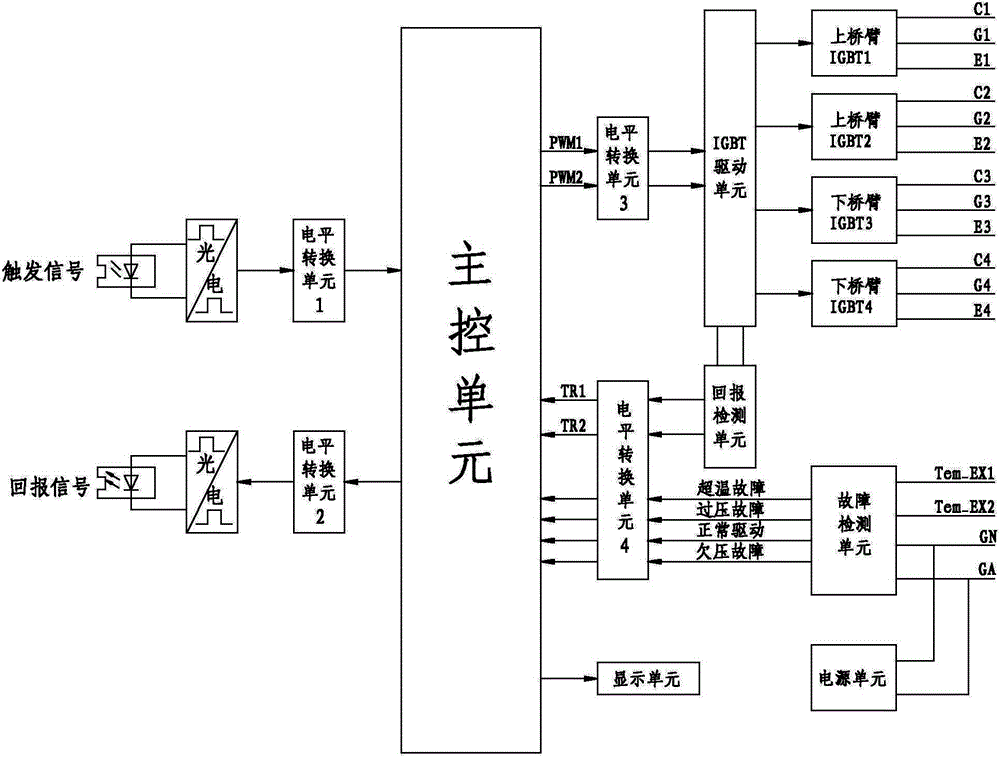

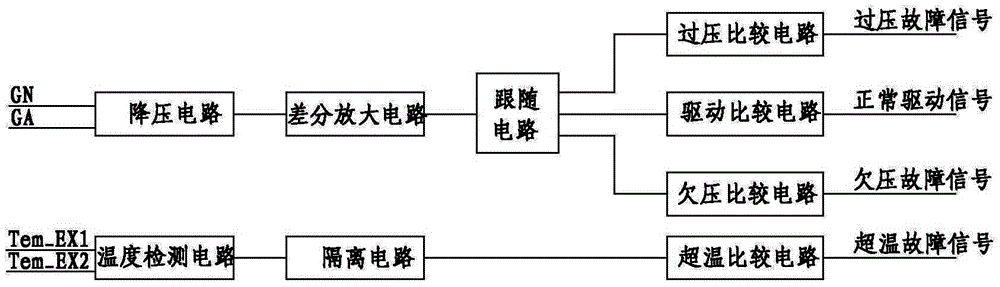

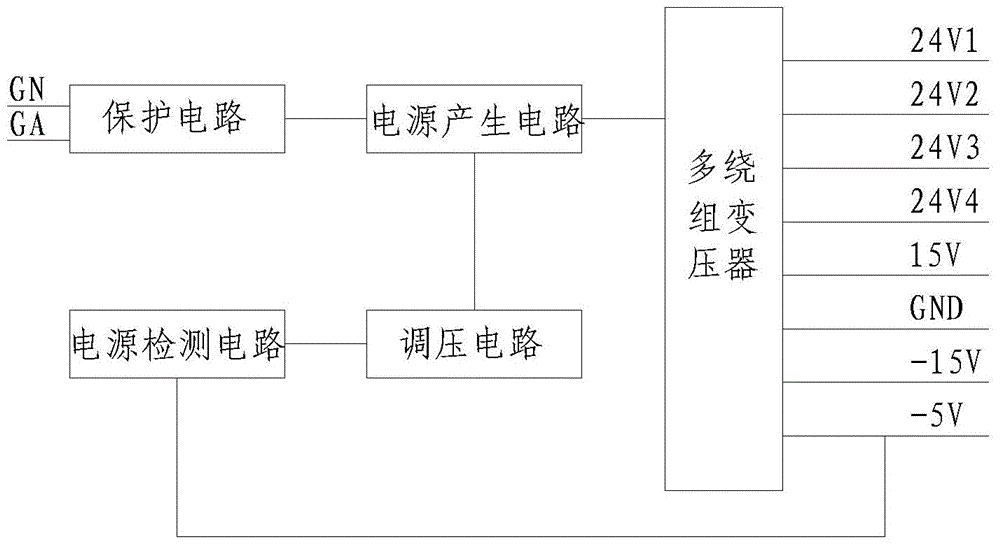

[0014] See figure 1 , an intensive SVG power unit drive board, characterized in that, with the main control unit as the core, it receives the trigger signal of the control system and sends a return signal to the control system at the same time; after the trigger signal passes through the photoelectric converter and the level conversion unit 1 , the trigger signals PWM1 and PWM2 are formed by the main control unit, after passing through the level conversion unit 3, the control signals C1, G1, E1 of the upper arm bridge IGBT1, the control signals C2, G2, E2 of the IGBT2 are output through the IGBT drive circuit, and the lower arm bridge The control signals C3, G3, E3 of the bridge IGBT3, and the control signals C4, G4, E4 of the IGBT4; the IGBT drive unit is also connected to the return detection unit, and through the level conversion unit 4, return signals TR1 and TR2 are formed and sent to the main control unit; The temperature detection switch output terminals Tem_EX1, Tem_EX...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com