Electrolyzer maintenance power supply method and structure

A technology for repairing power supply and power supply method, which is applied in the direction of electrical components, panel/switch station circuit devices, substation/switch layout details, etc., and can solve the problems of difficult construction, high maintenance cost, and many fault points of the power supply circuit for electrolyzer repair. problems, to achieve the effect of simplifying construction difficulty, reducing repair and maintenance, and reducing electrical accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

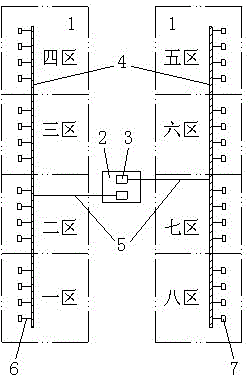

[0019] In specific implementation, such as figure 1 As shown, the power distribution room can be built in the middle between the two existing parallel factory buildings. If the existing power distribution room itself is built in the middle between the two factory buildings, the existing power distribution room can also be used. The power distribution room is equipped with two output power sources, which are the power sources for the electrolyzer maintenance box. Then lay busway 4 in two factory buildings, and busway is laid along the arrangement direction of electrolyzer in the factory building, and electrolyzer is arranged by factory building length direction at present, so busway is also laid by factory building length direction. One group of electrolyzer inspection boxes 7 is arranged on one side of the bus duct, the electrolyzer inspection boxes may be existing, and the electrolyzer inspection boxes are evenly distributed along the length direction of the factory buildi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com