Hybrid genetic simulated annealing algorithm for solving job shop scheduling problem

A simulated annealing algorithm and job scheduling technology, applied in genetic rules, calculations, genetic models, etc., can solve the problems of poor time performance of SA algorithm and very strict global convergence requirements, and achieve reduced calculations, convenient operation, and convenience The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described in detail below with reference to the drawings and embodiments.

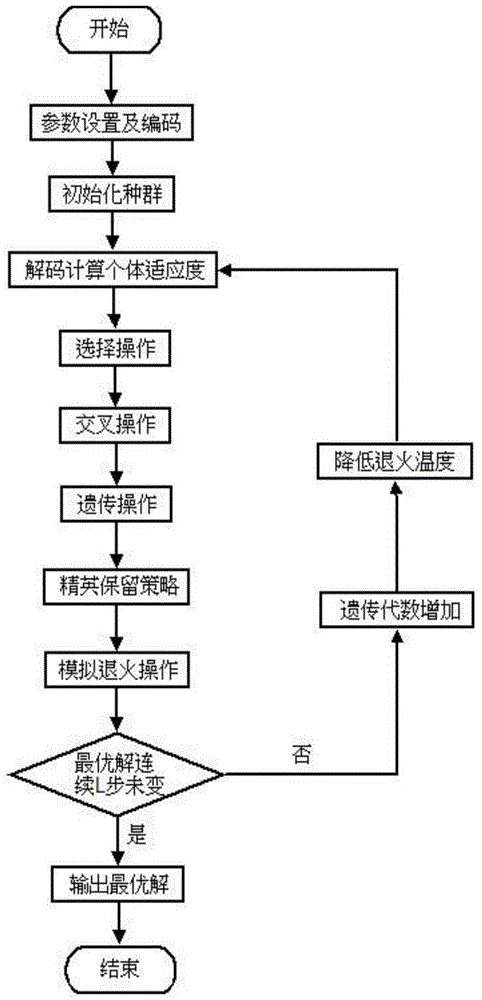

[0061] In order to overcome the limitations of the traditional genetic algorithm to solve the job-shop scheduling problem, the present invention combines the simulated annealing algorithm and the genetic algorithm, and proposes a new genetic simulated annealing (GASA) hybrid algorithm. The genetic algorithm has poor local search capabilities, but has a strong ability to grasp the overall search process; while the simulated annealing algorithm has strong local search capabilities and can prevent the search process from falling into the local optimal solution, but the simulated annealing algorithm has The condition of the search space is not well understood, and it is inconvenient for the search process to enter the most promising search area, which makes the operation efficiency of the simulated annealing algorithm inefficient. However, if the genetic algorithm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com