Metering device and metering method for marshall compaction testing apparatus for asphalt mixture

A technology of asphalt mixture and metering device, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems that the contact between the compaction hammer and the compacted surface of the test piece cannot be guaranteed, the compaction effect of the test piece is difficult to be guaranteed, and the problem is not enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

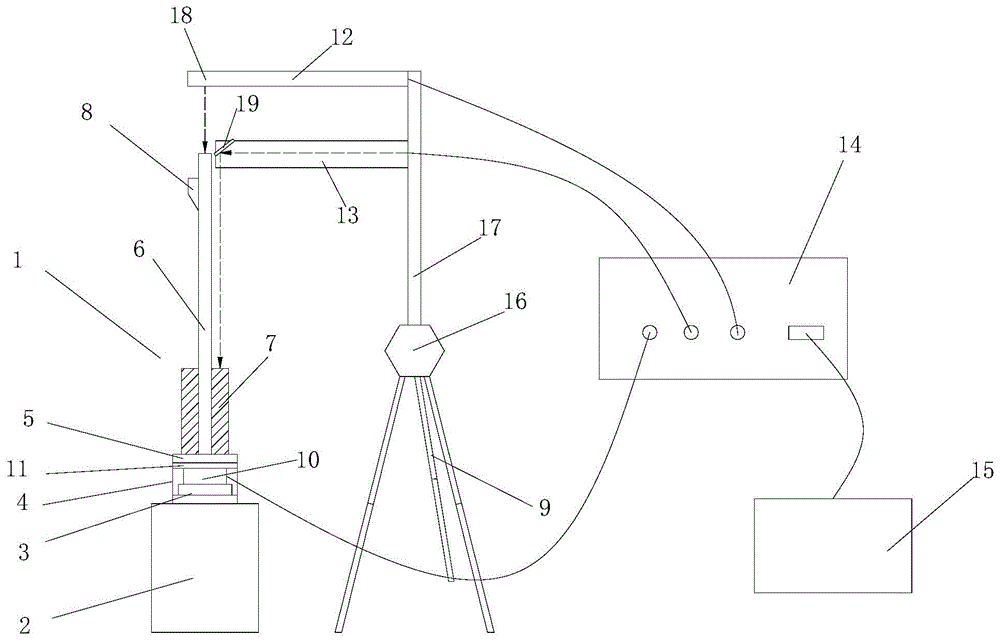

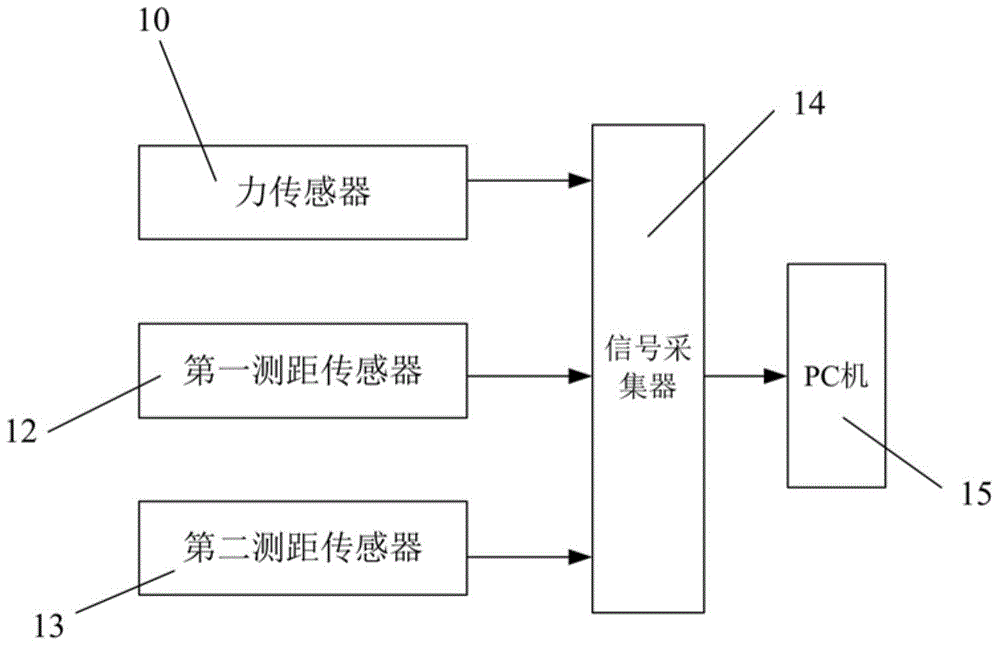

[0031] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0032] like figure 1 and figure 2 As shown, a metering device of Marshall compaction meter for asphalt mixture is used to quantitatively measure the effect of hammer 7 of Marshall compaction meter 1 of asphalt mixture on the forming of test pieces. In order to clearly show the metering device of Marshall compaction meter for asphalt The specific implementation manner of the asphalt mixture Marshall compaction instrument 1 is described here. The asphalt mixture Marshall compaction instrument 1 includes a wooden pier 2, a compaction head 5, a guide rod 6, and a compactor set on the guide rod 6. Hammer 7, the limit block 8 that is located at guide bar 6 tops, compaction head 5 and guide bar 6 are integral structures, and when testing, asphalt mixture sample is put between wooden pier 2 and compaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com