Sand-containing gas sand collecting device in gas well sand production and sand control simulation experiment

A simulation experiment and sand control technology, applied in measurement devices, sampling devices, instruments, etc., can solve the problems of experimental data analysis errors, inability to monitor gas flow at the same time, etc., to achieve the effect of convenient operation, satisfying experimental requirements and simple principles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

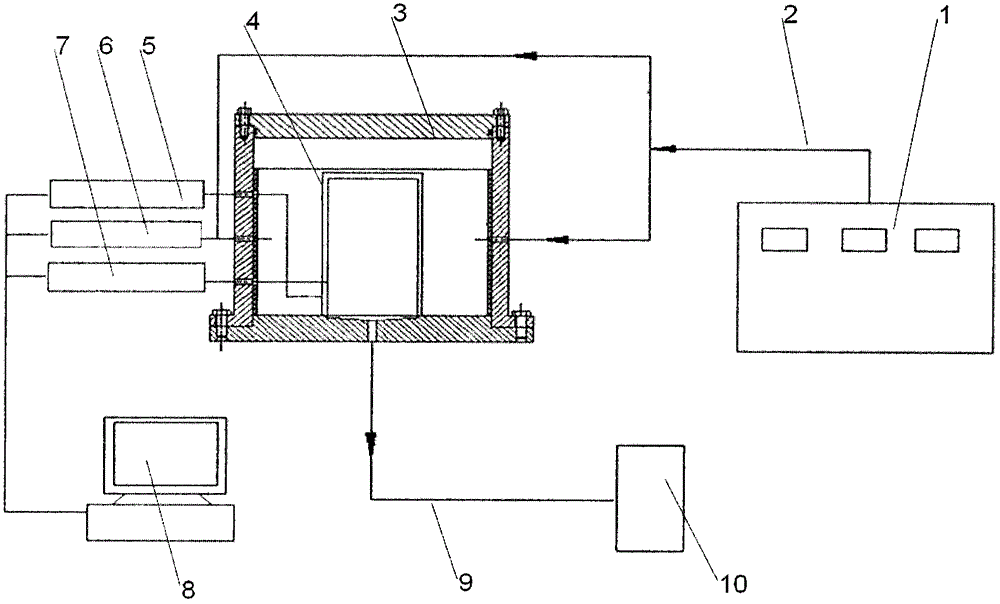

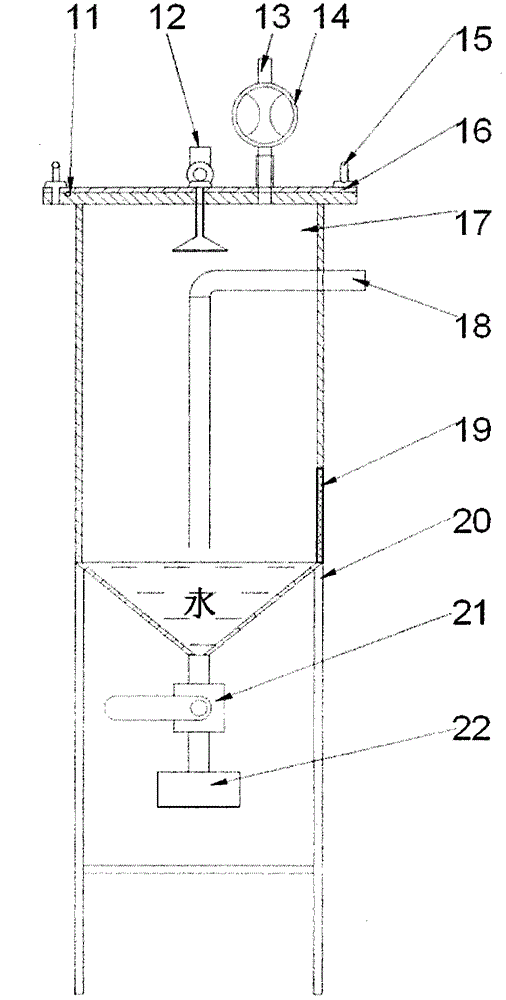

[0014] like figure 1 and figure 2 As shown in the figure, it is the flow chart of the sand control simulation experiment of gas well output and the sand-containing gas sand collecting device of the patent of the present invention, which includes a pressure-stabilized air supply pump 1, a gas transmission pipeline 2, a closed autoclave 3, a sand control pipe 4, and an annular external pressure sensor. 5. Inlet pressure sensor 6, annular pressure sensor 7, pressure data acquisition system 8, gas outlet pipeline 9, sand-containing gas sand collecting device 10, sealing ring 11, atomizing nozzle 12, air outlet 13, flow meter 14, lifting ring 15 , the upper bottom gland 16 , the tank 17 , the air inlet 18 , the observation window 19 , the bracket 20 , the ball valve 21 , and the multi-stage sorting device 22 . The patented device of the present invention is characterized in that the upper part is a cylinder, the lower part is an inverted cone, and the structural components are, f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com