A High Precision Dynamic Thrust Test System of Micro Pyrotechnic Actuator

A dynamic thrust, testing system technology, applied in measuring devices, force/torque/work measuring instruments, measurement of elastic deformation force through measuring gauges, etc. Different problems, different weights, etc., to achieve the effect of improving installation efficiency and measurement consistency, introducing small errors, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

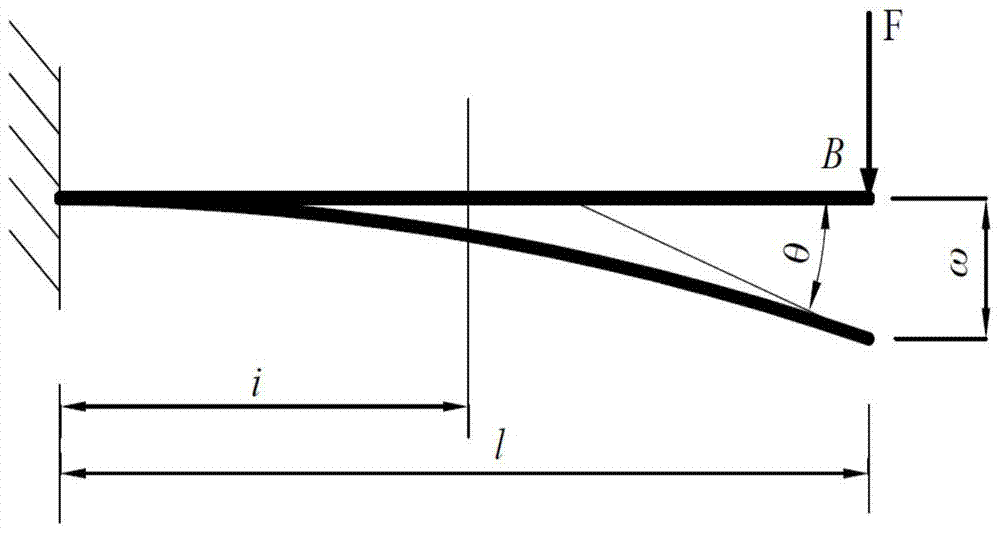

[0021] exist figure 1 In , the strain sensor is installed at a distance from the fixed end i of the cantilever beam, and the thrust F generated by the piston of the pyrotechnic device acts on the position B of the cantilever beam, thus causing the cantilever beam to bend, and the strain gauge senses the stress change signal ε i , processed and recorded by the signal processor. After getting the strain signal ε i After that, the thrust F is calculated by the following formula.

[0022]

[0023] Where: ε i is the strain value at i, W is the bending section coefficient, W=bh 2 / 6, h is the height of the rectangular section of the cantilever beam, b is the width of the rectangular section of the moment cantilever beam, and E is the elastic modulus of the cantilever beam material. ε obtained by the strain sensor i The time-varying curve can accurately measure the thrust-time curve of the piston part of the pyrotechnic device.

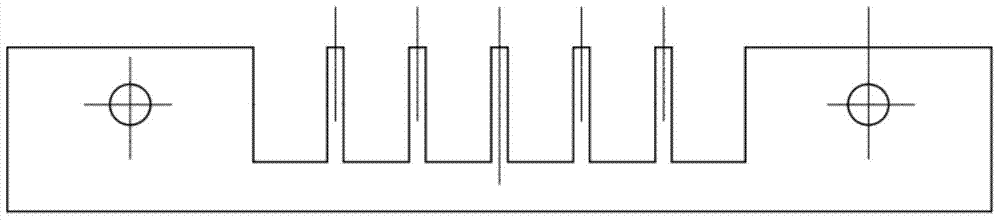

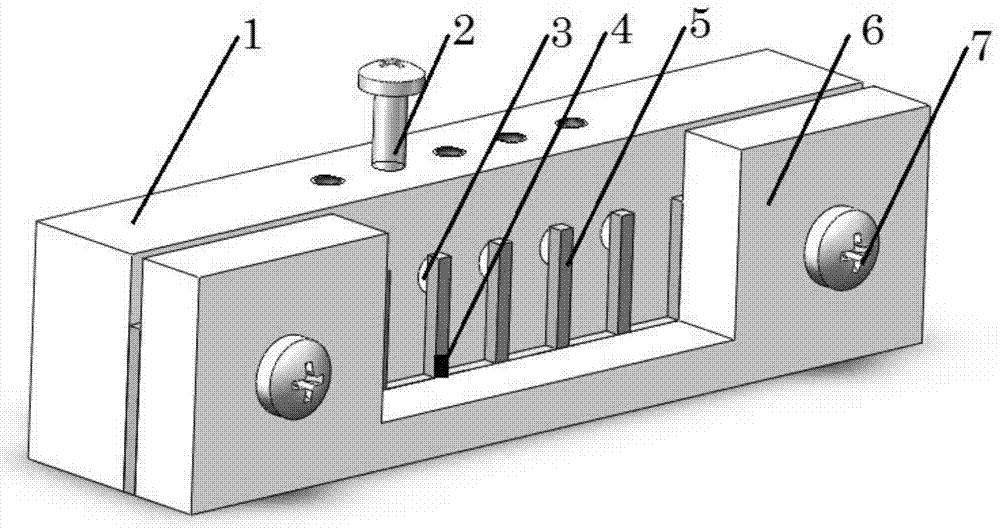

[0024] figure 2 The size and material of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com