Orthogonal stacked steel pipe lever tensioning device

A fastening device and tensioning technology, applied in the direction of building structure support, building structure support, scaffolding connection, etc., can solve the problems of low operation efficiency, cumbersome, high manufacturing cost, etc., achieve convenient installation and disassembly, ensure safe use, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The applicant will describe in detail in the form of the following examples, but the description of the examples is not a limitation to the technical solution of the present invention, and any equivalent transformation made according to the concept of the present invention is only a formal rather than a substantive equivalent transformation All should be regarded as the scope of the technical solution of the present invention.

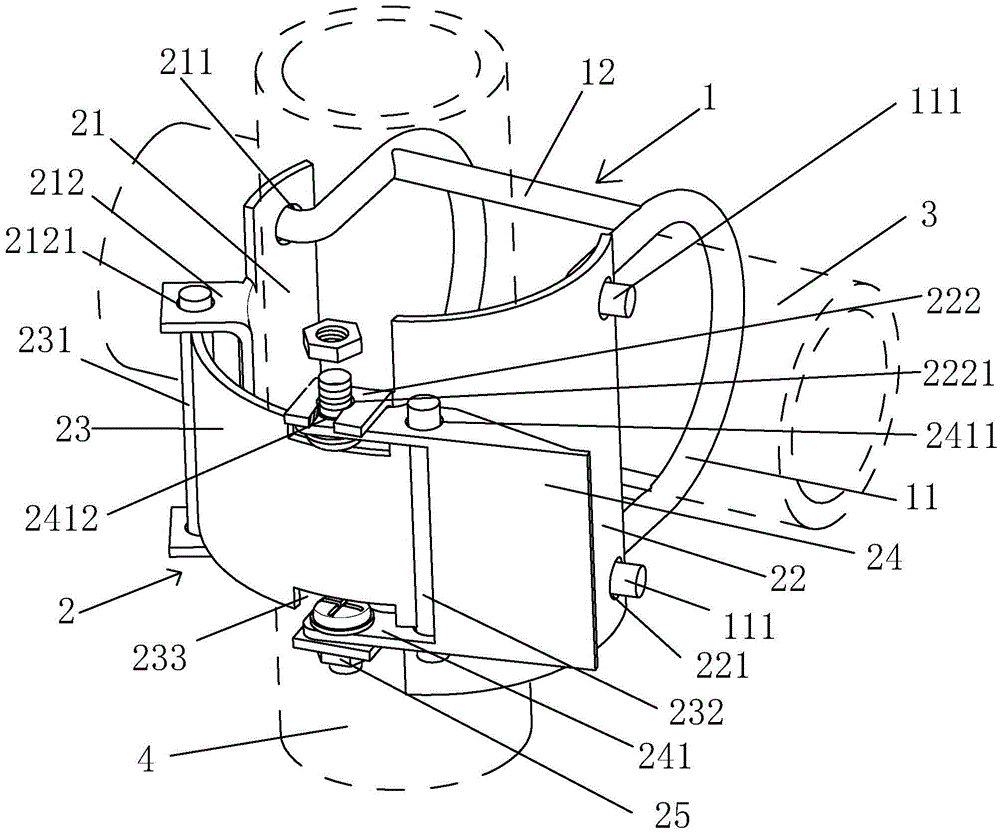

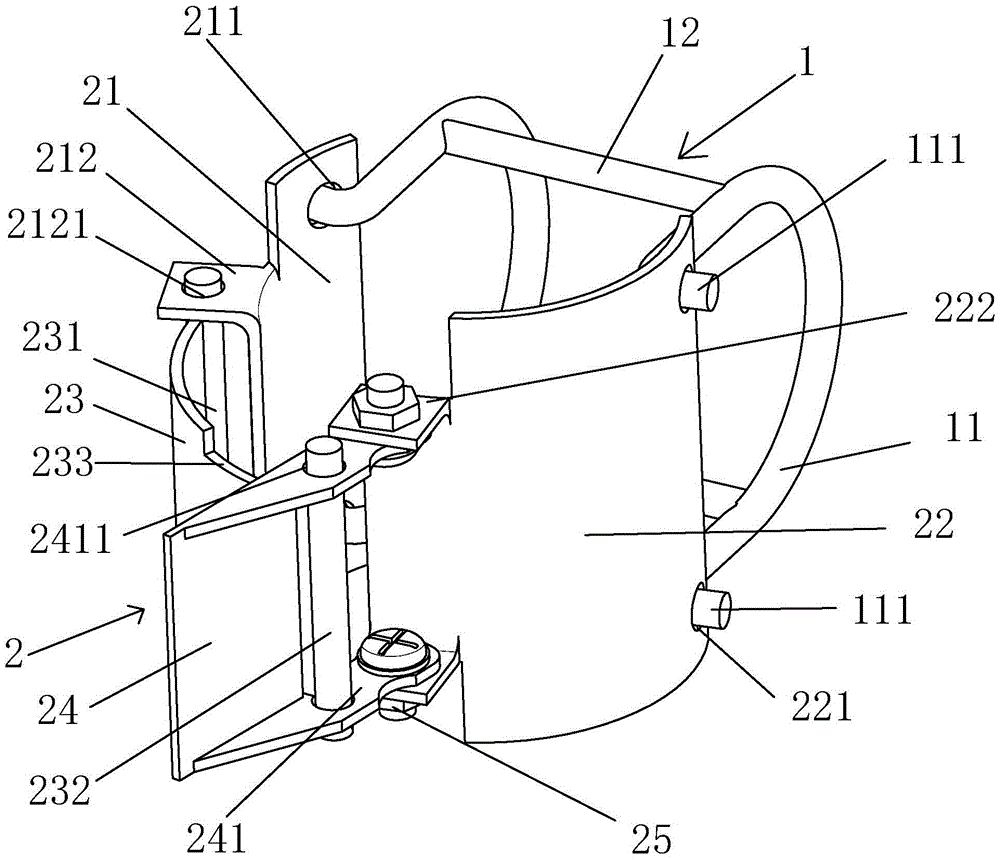

[0019] see figure 1 and combine figure 2 , The present invention relates to an orthogonally stacked steel pipe lever tensioning type fastening device, comprising a clamp 1 and a tensioning mechanism 2, and the clamp 1 and the tensioning mechanism 2 are matched and connected. The tensioning mechanism 2 is composed of a short tensioning plate 21, a long tensioning plate 22, a connecting plate 23, a pull button 24 and a hinge 25, and the short tensioning plate 21 is provided on one side in the length direction. There is a pair of first connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com