Preparation and application of a nanostructured composite adsorbent material

A nanostructure composite and adsorption material technology is applied in the preparation of nanostructure composite adsorption materials and the preparation of maleic acid modified mesoporous silicon materials, which can solve problems such as air pollution and water pollution, and achieve high selective adsorption and separation. , Improve the adsorption capacity, the preparation process is simple and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Dissolve 500mg of CTAB in 240mL of distilled water, keep stirring mechanically, add 1.75mL of sodium hydroxide solution and 0.5mL of TEOS dropwise after half an hour. React at 80°C for 2 hours, centrifuge, and wash with ethanol three times. A mesoporous silicon material is obtained.

[0035] (2) Dissolve 1 g of the mesoporous silicon material in step (1) in 75 mL of toluene. Add 2 mL of APTES dropwise, and reflux for one day to obtain a silane-modified mesoporous silicon material.

[0036] (3) Disperse 0.25 g of the silane-modified mesoporous silicon material obtained in (2) in 15 mL of DMF, and then add 0.35 g of maleic anhydride (MA) and 0.25 mL of pyridine. Under the protection of nitrogen, react at 50°C for 3 hours, and the solution system turns reddish brown. Filter and dry to obtain the maleic acid modified mesoporous composite material.

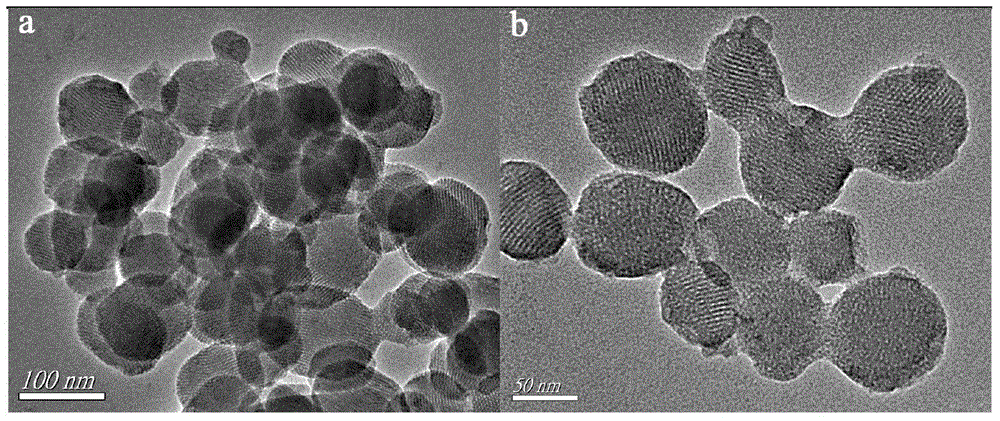

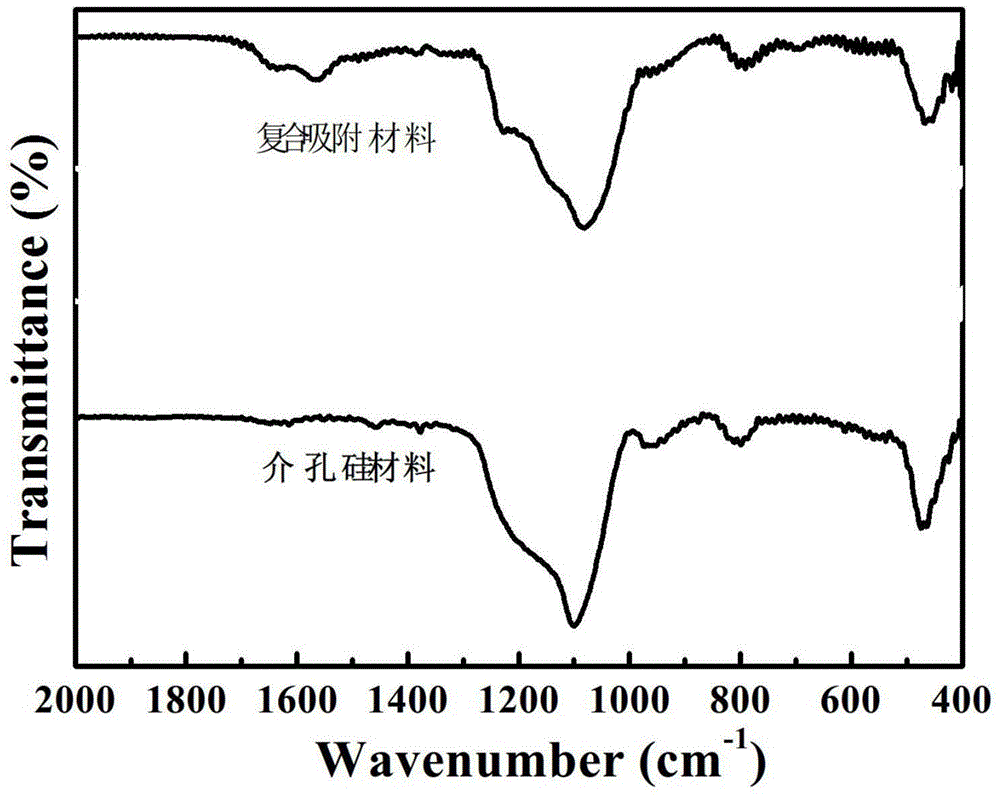

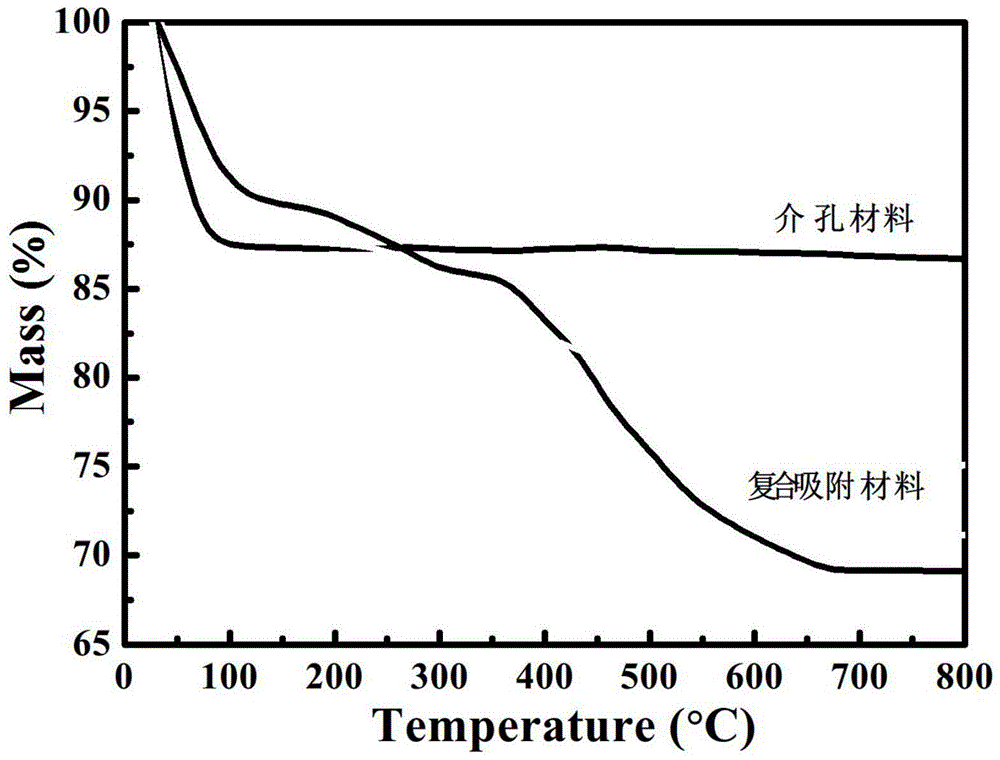

[0037] (5) The transmission electron microscope pictures of mesoporous silicon materials and nanostructured composite ...

Embodiment 2

[0041] (1) Dissolve 400mg of CTAB in 200mL of distilled water, keep stirring mechanically, add 1.45mL of sodium hydroxide solution and 0.414mL of TEOS dropwise after half an hour. React at 80°C for 2 hours, centrifuge, and wash with ethanol three times. A mesoporous silicon material is obtained.

[0042] (2) Dissolve 2.06 g of the mesoporous silicon material in step (1) in 160 mL of toluene. 4.267mL of APTES was added dropwise and refluxed for one day to obtain a silane-modified mesoporous silicon material.

[0043] (3) Disperse 0.32 g of the silane-modified mesoporous silicon material obtained in (2) in 20 mL of DMF, and then add 0.46 g of maleic anhydride (MA) and 0.333 mL of pyridine. Under the protection of nitrogen, react at 50°C for 3 hours, and the solution system turns reddish brown. Filter and dry to obtain the maleic acid modified mesoporous composite material.

[0044](5) The TEM images of mesoporous silicon materials and nanostructured composite adsorbents are ...

Embodiment 3

[0054] (1) 201.6 mg of CTAB was dissolved in 96 mL of distilled water, kept under mechanical stirring, and 0.7 mL of sodium hydroxide solution and 0.2 mL of TEOS were added dropwise after half an hour. The reaction was carried out at 80 °C for 2 h, centrifuged, and washed three times with ethanol. A mesoporous silicon material is obtained.

[0055] (2) Dissolving 1.3 g of the mesoporous silicon material in step (1) in 100 mL of toluene. 2.667 mL of APTES was added dropwise and refluxed for one day to obtain a silane-modified mesoporous silicon material.

[0056] (3) Disperse 0.425 g of the silane-modified mesoporous silicon material obtained in (2) in 25 mL of DMF, and then add 0.587 g of maleic anhydride (MA) and 0.417 mL of pyridine. Under the protection of nitrogen, react at 50 °C for 3 h, and the solution system becomes reddish-brown. Filtration and drying to obtain maleic acid modified mesoporous composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com