Small fast filter tank equipped with air-water backwashing system and its filtration and backwashing process

A technology of backwashing and quick filter, applied in the direction of loose filter material filter, filtration separation, gravity filter, etc., can solve the problems of small scale of water supply and imperfect construction of water supply facilities, and achieve less flushing water and flushing effect. Good, long filtration cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

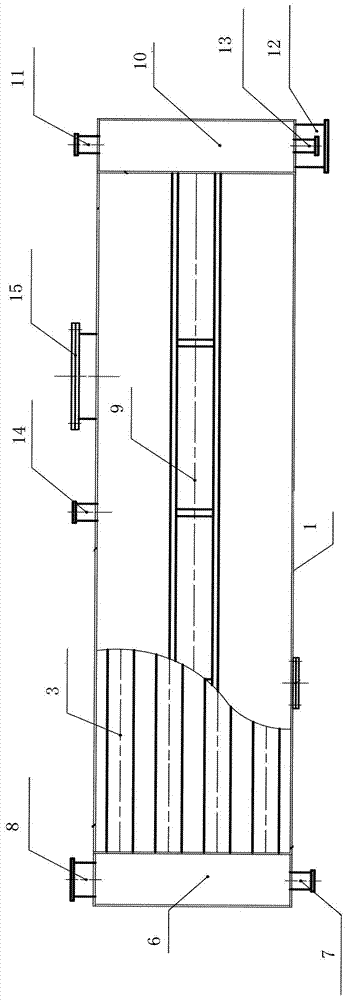

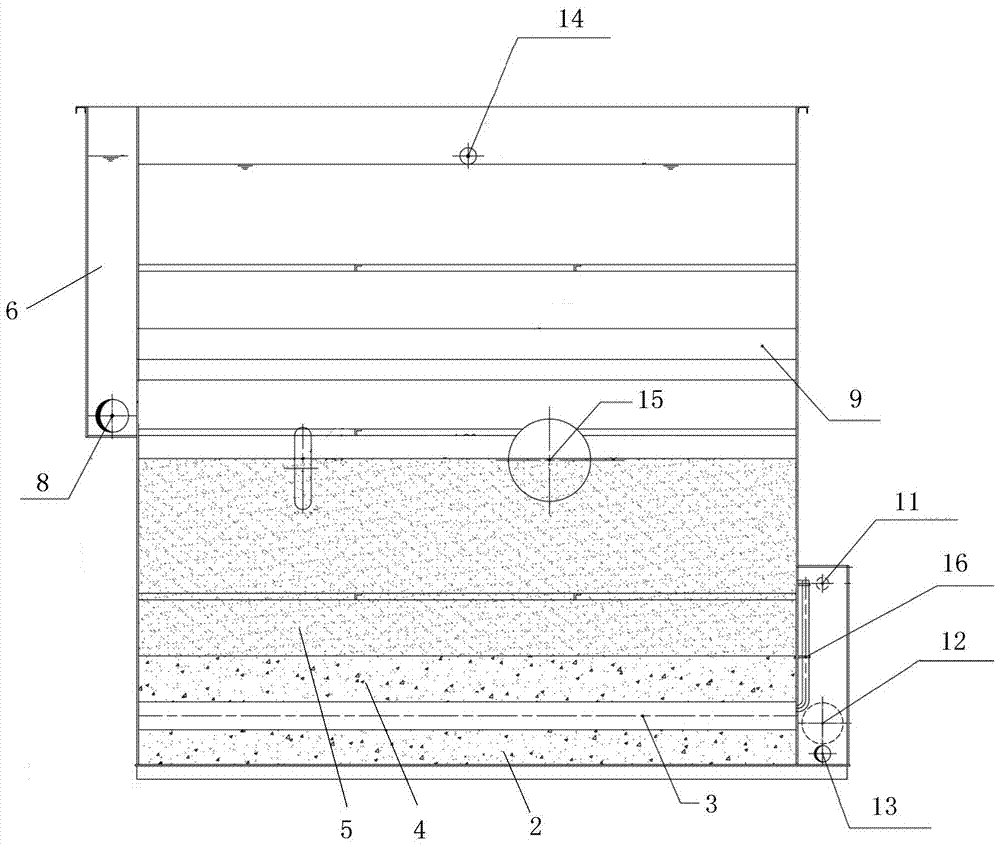

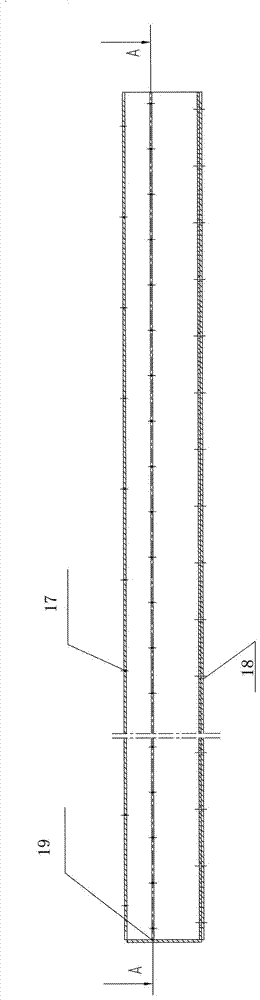

[0014] Such as figure 1 and figure 2 As shown, a small fast filter tank equipped with an air-water backwashing system includes a filter tank main body 1, and is characterized in that a filter material layer 5 is arranged in the filter tank main body, and a water distribution pipe 3 is arranged at the bottom of the filter material layer 5, The water distribution and air distribution pipe is used as a water collecting device and a water distribution and air distribution device for air and water backwashing at the same time. The top and side walls of the water distribution and air distribution pipe are provided with backwashing air holes, and the bottom of the pipe is provided with backwashing water holes. The quick filter adopts water distribution and gas distribution pipe as the water distribution and gas distribution device for gas water backwashing. The filtration area of the fast filter is 4m 2 , the plane size is 1.00m × 4.00m, from the bottom of the filter tank to set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com