A kind of plant polysaccharide cleaning liquid

A technology of plant polysaccharides and cleaning fluids, applied in the field of medicine, to achieve good biological safety, meet clinical application requirements, and long-lasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

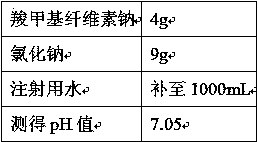

[0023] Using sodium carboxymethyl cellulose with different mass percentages and degrees of substitution as raw materials, the process of preparing plant polysaccharide cleaning solution: weigh sodium carboxymethyl cellulose as shown in Table 1, and mix carboxymethyl cellulose with stirring. Sodium cellulose is dissolved in water for injection. After fully dissolving, add 9g of sodium chloride, 0.811g of potassium dihydrogen phosphate, and 0.189g of sodium hydroxide, fully stir and dissolve, and finally make up to 1000ml with water for injection, measure the pH value, and filter , the filtrate is filled and sealed, and steam sterilized at 121°C for 30 minutes.

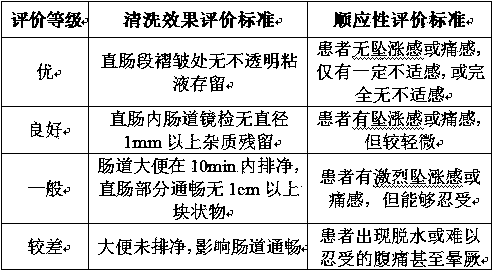

[0024] Table 1 Determination of parameters of sodium carboxymethyl cellulose

[0025] .

Embodiment 7~9

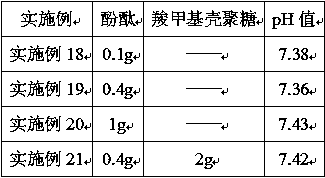

[0027] The preparation process of further adding carboxymethyl chitosan plant polysaccharide cleaning solution: take by weighing 5 g of sodium carboxymethyl cellulose with a degree of substitution of 0.62, and dissolve sodium carboxymethyl cellulose in water for injection under stirring, and wait until fully After dissolving, add 9g of sodium chloride, 0.811g of potassium dihydrogen phosphate, 0.189g of sodium hydroxide, carboxymethyl chitosan, fully stir to dissolve, and finally make up to 1000ml with water for injection, measure the pH value, filter, and fill the filtrate Seal; sterilize by steam at 121°C for 30 minutes, ready to serve. The amount of carboxymethyl chitosan added is shown in Table 2.

[0028] Table 2 Addition amount of carboxymethyl chitosan

[0029]

Embodiment 10~13

[0031] The preparation process of the plant polysaccharide cleaning liquid further adding magnesium chloride: Weigh 5 g of sodium carboxymethyl cellulose with a degree of substitution of 0.62, and dissolve sodium carboxymethyl cellulose in water for injection under stirring. After fully dissolving, add Sodium chloride 9g, potassium dihydrogen phosphate 0.811g, sodium hydroxide 0.189g, magnesium chloride and carboxymethyl chitosan 4g, fully stir to dissolve, and finally make up to 1000ml with water for injection, measure the pH value, filter, fill and seal the filtrate ; 121 ℃ steam sterilization for 30 minutes, that is. The amount of magnesium chloride added is shown in Table 3.

[0032] Table 3 The amount of magnesium chloride added

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com