Analog load cell with digital compensation

A load cell and analog signal technology, applied in the field of load cells, can solve the problems of limiting the universal connectivity of instruments or other peripherals, complex analog load cell interfaces, etc., to achieve the effect of good dynamic follow performance and simple interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

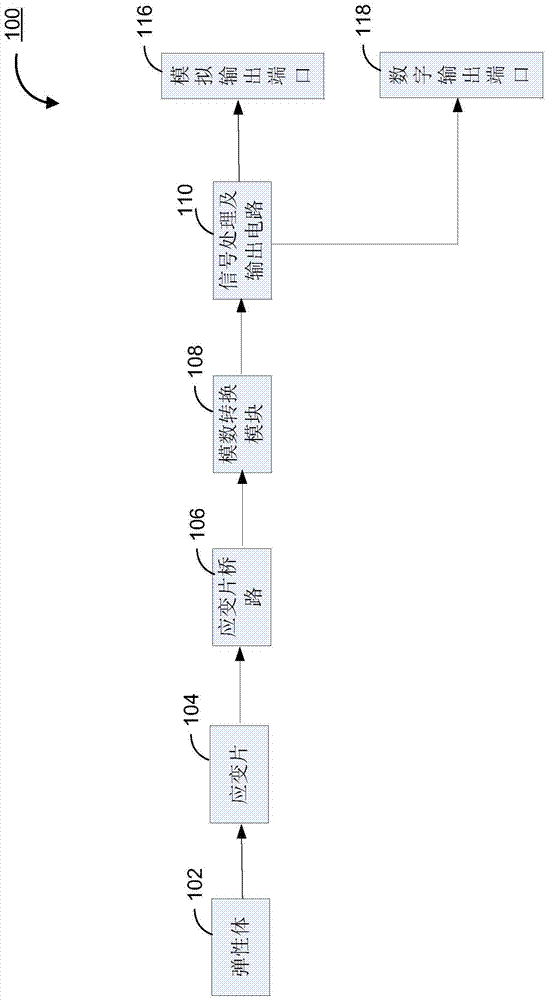

[0028] figure 1 is a schematic diagram of an analog load cell according to an embodiment of the present invention. Such as figure 1 As shown, the analog load cell 100 includes: an elastic body 102, the elastic body deforms according to the pressure sensed by the analog load cell; a strain gauge 104, the strain gauge is connected to the elastic body And produce the change of resistance value according to described deformation; A strain gauge bridge circuit 106, described strain gauge bridge circuit is connected to described strain gauge, transmit the change of described resistance value to output the first analog signal; One analog-to-digital conversion Module 108, connected to the output terminal of the strain gauge bridge circuit of the analog load cell, receives the first analog signal from the strain gauge bridge circuit, and converts the first analog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com