Asphalt rolling method for high-speed ring road in test field

A high-speed ring road and test field technology, which is applied to the coagulation pavement, roads, roads and other directions paved on site, can solve the problems such as the construction method and public report of asphalt sub-spreading on the surface of the high-speed ring road in the test field. Achieve the effect of strong practicability, simple principle and strong feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

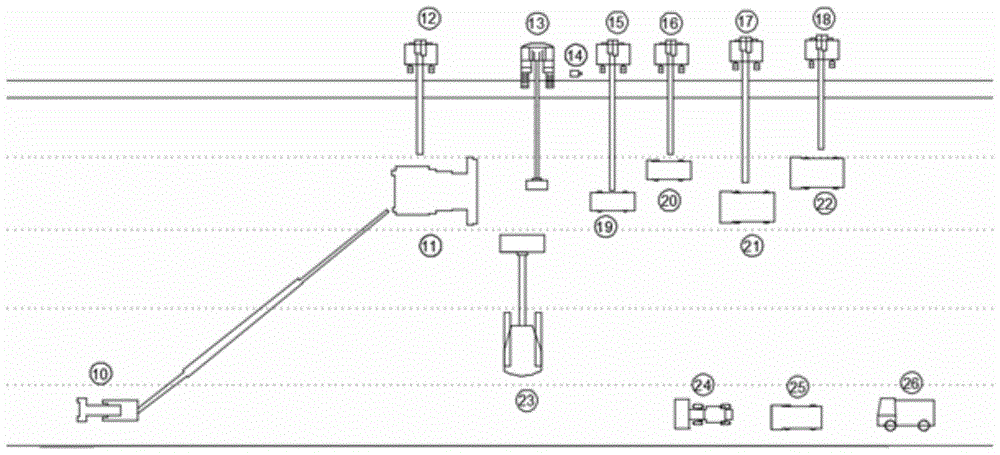

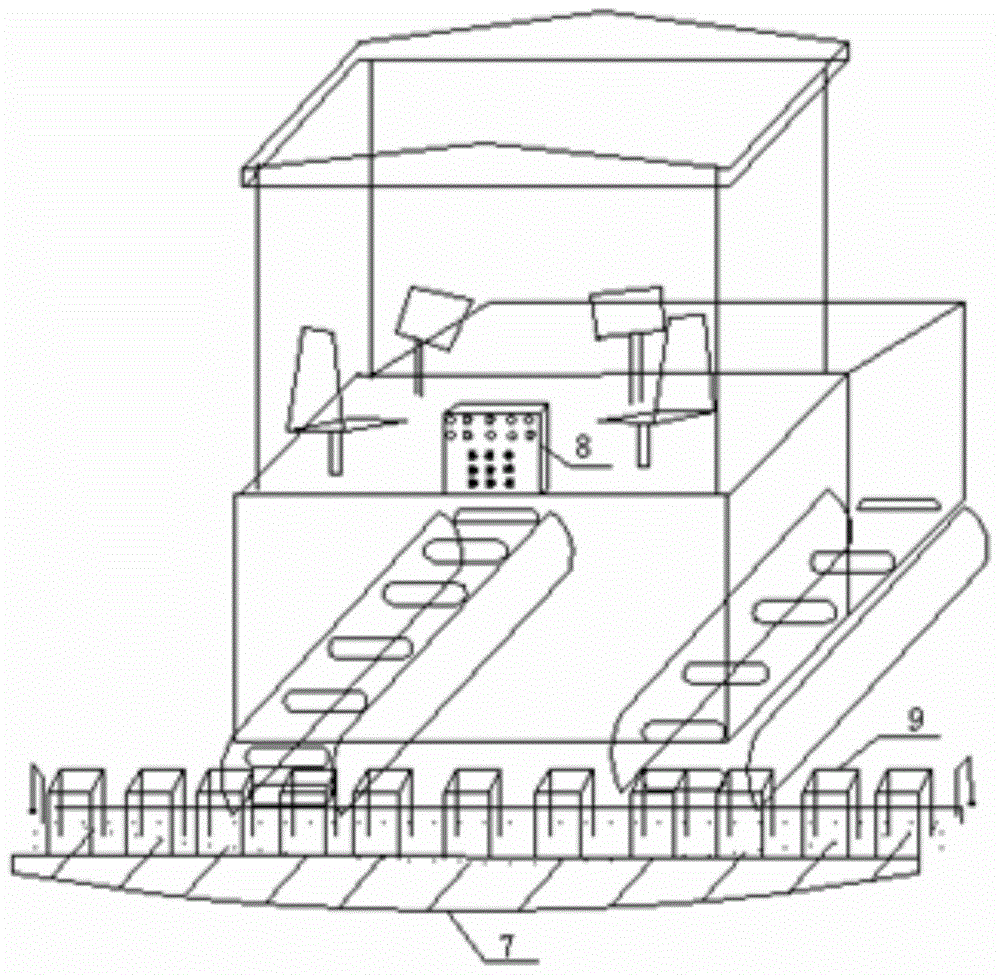

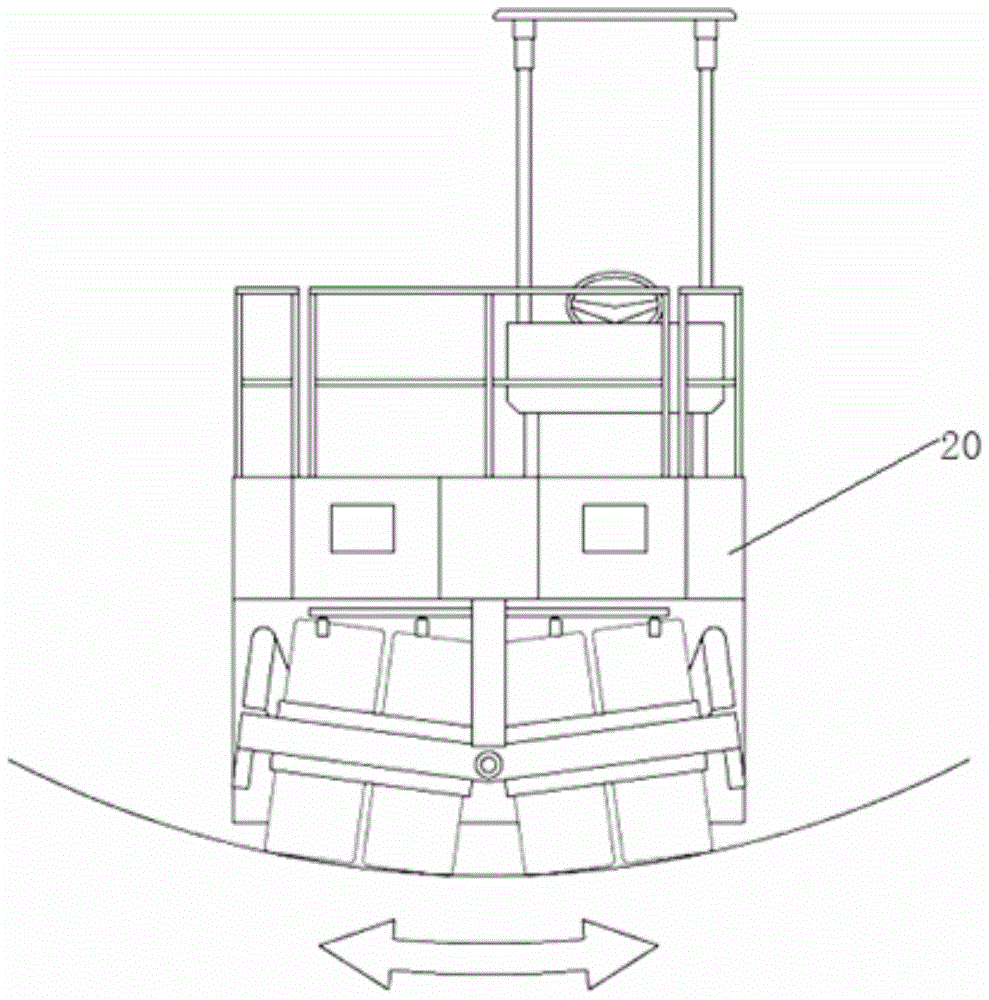

[0016] See the attached picture, the asphalt rolling method of the high-speed ring road surface of the test track, the formwork is erected on the driving lane before the asphalt road pavement of the high-speed ring road is paved, so as to ensure the uniformity of the overall loose paving coefficient of the paved road surface, and the pavement is divided into lanes according to the width of the road surface. In order to ensure the overall continuity of the roadway without transverse joints during paving, the slope combined machine is used to carry out rolling along the direction of traffic. The longitudinal joints of each layer of construction are staggered, which does not affect the overall smoothness, and the position of the joints of the surface layer is on the marking line, and is divided by lanes. The specific rolling steps are:

[0017] For the ring road with a cubic parabolic curved surface, asphalt paving adopts a complete set of operating machinery, including asphalt fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com