Double-sleeve

A double-sleeve and outer-pipe technology, applied in the field of double-sleeves, can solve the problems of low mixing concentration, easy to block the pipeline, and increase the maintenance amount, and achieve the effect of speeding up material transportation, ensuring effectiveness, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

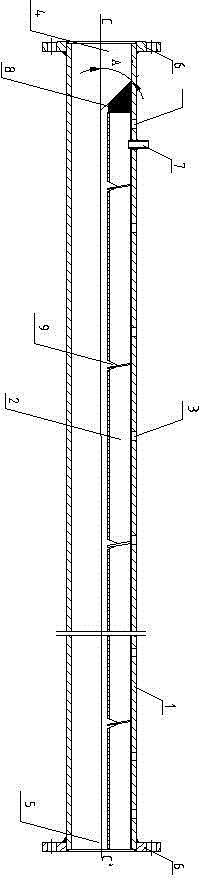

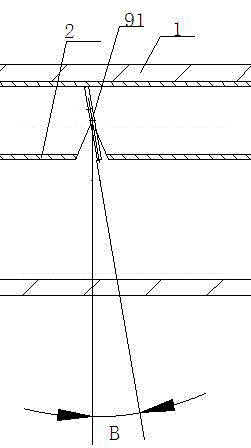

[0018] As shown in the figure, a double casing includes an outer tube 1 and an inner tube 2, wherein both the outer tube 1 and the inner tube 2 have a circular structure, and the top of the outer tube 1 is provided with 8 welding holes 3 , the welding holes 3 are distributed in a straight line, the inner pipe 2 is located at the top of the outer pipe 1, and the inner pipe 2 is welded on the inner wall of the outer pipe 1 through the welding holes 3; one end of the double casing is an inlet end 4, one end is an outlet end 5, and the two ends are provided with a fixed ring 6, and the fixed ring 6 is fastened to the outside of the outer tube 1; the outer top of the double casing is provided with an air inlet pipe 7, and the The air inlet pipe 7 runs through the wall of the outer pipe 1, the bottom of the air inlet pipe 7 is connected to the inside of the inner pipe 2, and one end of the inner pipe 2 is provided with a sealing head 8, which is close to the inlet end 4, and the seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com