Full-plastic anti-counterfeiting cap, aluminum plastic anti-counterfeiting cap and combining connection sleeve used for anti-counterfeiting caps

A combined connection and pseudo-cap technology, applied in the directions of transportation and packaging, packaging, locking equipment, etc., can solve the problems of unfavorable bottle cap decorative parts distribution design, excessive use of materials for inner sleeves, and high production costs, and reduce the amount of materials used. Production cost and overall length reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

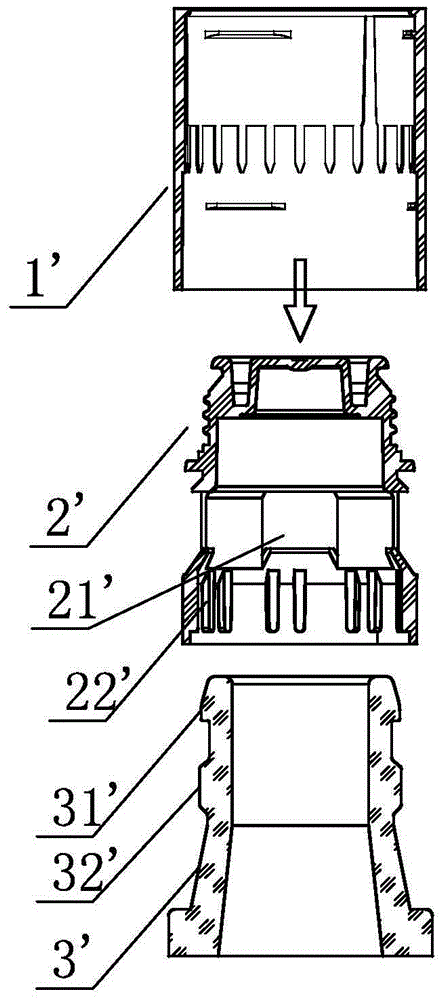

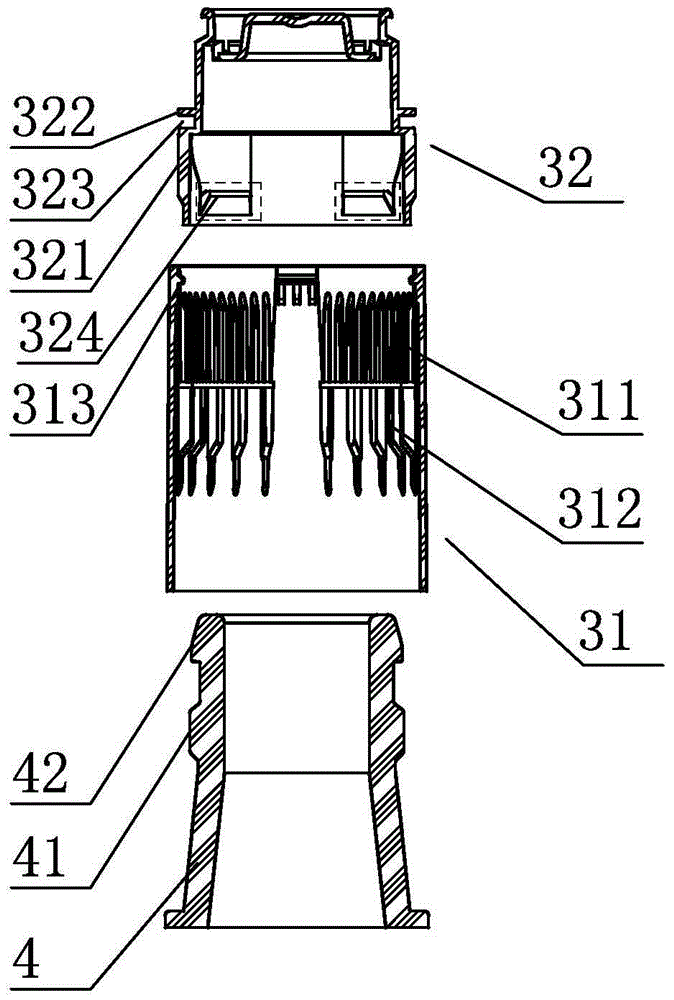

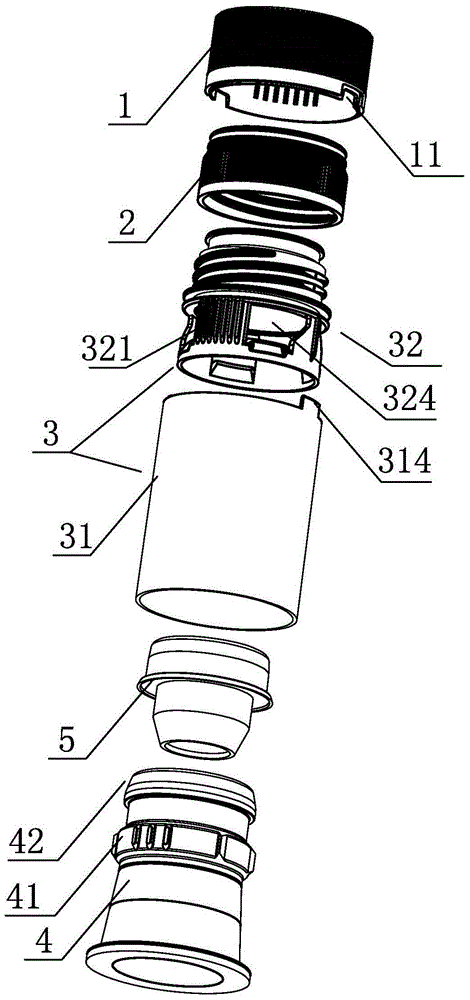

[0021] Such as figure 2 and 3 As shown, the all-plastic anti-counterfeiting cover of this embodiment includes an outer cover 1 and an inner cover 2 with internal threads, and the inner cover 2 is fixed in the outer cover 1 by gluing, or fixed in the outer cover 1 by a non-rotation structure. The cover 1 and the inner cover 2 are fixed on the bottle mouth 4 through the combined connecting sleeve 3, wherein the combined connecting sleeve 3 includes an outer cover 31 and an inner cover 32, the inner cover 32 is fixed in the outer cover 31, and the upper part of the inner cover 32 exposes the outer cover 31 and It has an external thread, and the inner sleeve 32 cooperates with the internal thread of the inner cover 2 through the external thread, and the inner cover 2 can be screwed on the inner sleeve 32, and the outer wall of the lower part of the inner sleeve 32 is provided with a lower stop gear 321, and the outer cover 31 The inner wall is provided with a first anti-rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com