Spectacle frame

A technology for spectacle frames and temples, which is applied in the field of spectacle frames, can solve problems such as higher manufacturing costs, increased manufacturing costs, and complex spring hinge structures, and achieve the effects of reduced manufacturing hours and lower costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

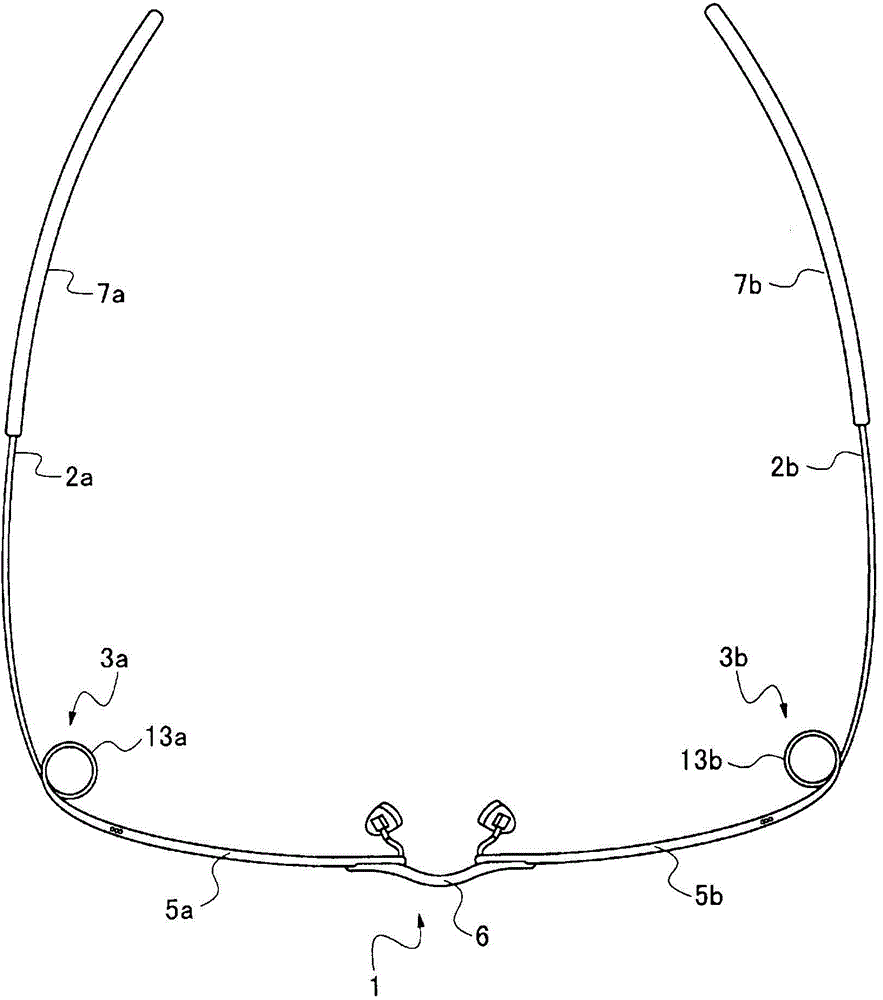

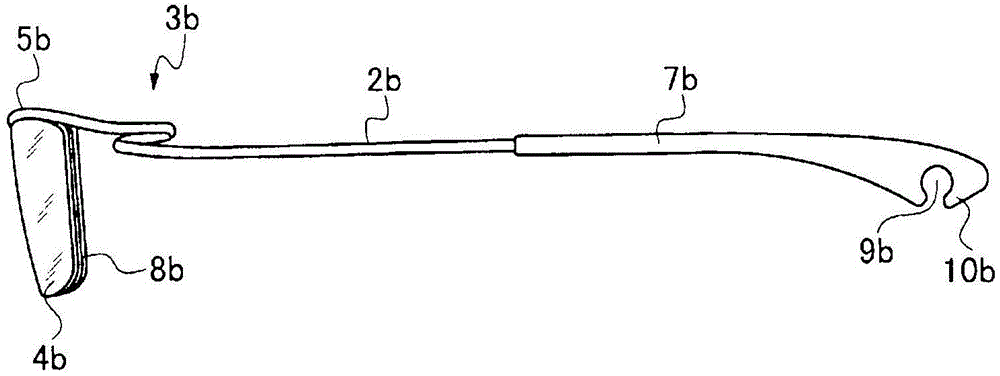

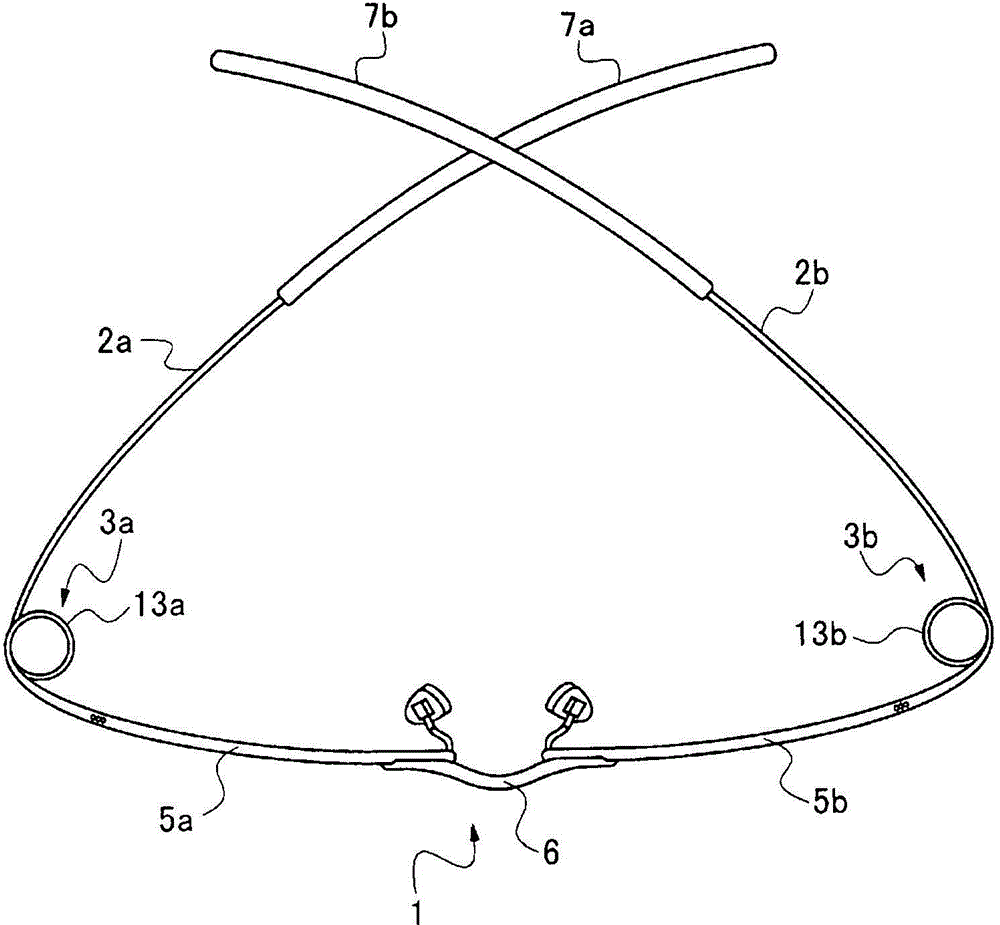

[0033] figure 1 , figure 2 It is a figure showing the spectacle frame of the first embodiment of the present invention, and reference numeral 1 denotes a front part, reference numerals 2a, 2b denote temples, and reference numerals 3a, 3b denote ring joint parts. The lenses 4a, 4b are symmetrically installed on the front part 1. Therefore, the lenses 4a, 4b are held by metal or plastic wires (Japanese: 水系) 8a, 8b, and the two ends of the metal or plastic wires 8a, 8b are fixed to the half frame 5a, 5b.

[0034] The two half-frames 5a, 5b are brazed by the connecting member 6 in the center, and are connected symmetrically. Furthermore, the half-frames 5a, 5b extend outward to form ring joints 3a, 3b, and further extend rearward from the ring joints 3a, 3b to form temples 2a, 2b. That is, the half-frames 5a, 5b, the annular joint portions 3a, 3b, and the temples 2a, 2b are each composed of one continuous wire. Furthermore, resin leg covers (ear hooks) 7a, 7b for hanging on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com