A High Field Permanent Magnet Magnetic Resonance Imaging Magnet System with Magnetic Focusing and Curved Surface Correction

A technology of magnetic resonance imaging and permanent magnets, applied in permanent magnets, measuring magnetic variables, measuring devices, etc., can solve the problems of small effective shimming space and low efficiency, and achieve high magnetic field stability, high efficiency, and shimming space big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

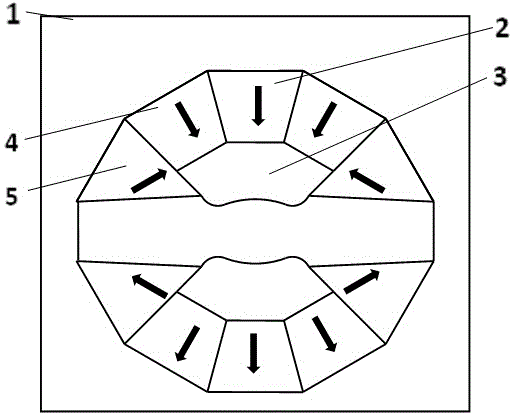

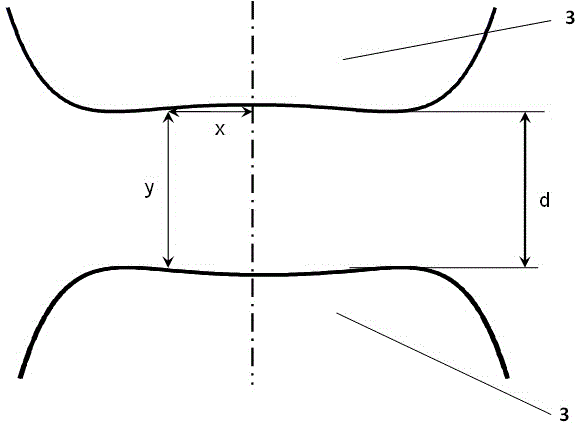

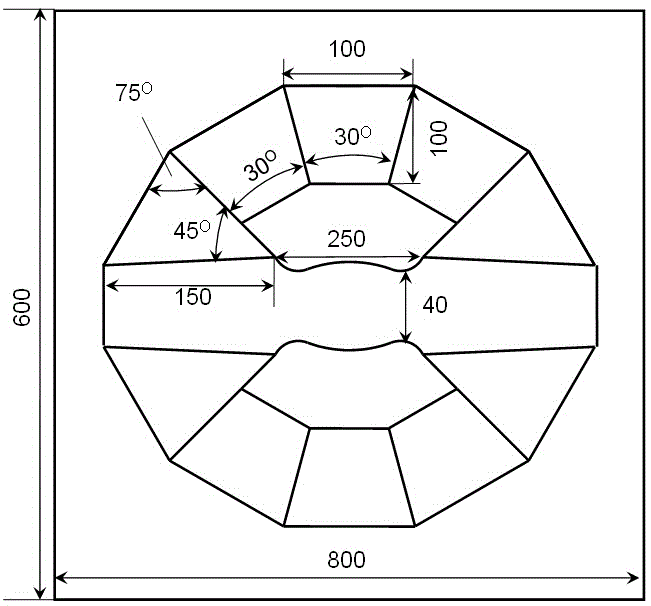

[0019] Two kinds of permanent magnet main magnets were made, one with a main magnetic field strength of 1.5T, a magnetic gap of 40mm, a shimming space of a cylinder with a diameter of 35mm×60mm, a weight of 400kg, and a uniformity of 0.5ppm. The data in Table 2 were used. image 3 The specific dimensions of its components are shown in .

[0020] The other one has a main magnetic field strength of 1.2T, a magnetic gap of 70mm, a shimming space of a cylinder with a diameter of 60mm×100mm, a weight of 1200kg, a space utilization efficiency of 92%, and a magnetic field uniformity of 2ppm. The data in Table 3 is used. Figure 4 The specific dimensions of its components are shown in .

[0021] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com