A special tooling for shell cover

A shell cover and tooling technology, applied in the field of tooling and fixtures, can solve problems such as troublesome placement and handling of workpieces, shaking of workpieces, bumps, etc., and achieve the effects of low production costs, improved work efficiency, and prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

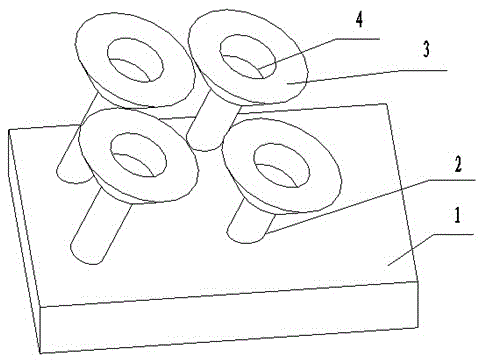

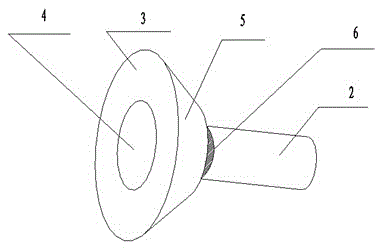

[0013] Such as figure 1 and figure 2 As shown, a special tooling for the shell cover plate of the present invention, the tooling includes a bottom plate 1, a support column 2, and a disc 3, and a concave cavity 4 with an upward opening is arranged on the upper surface of the disc 3, and the The structure of the concave cavity 4 matches the outer structure of the shell cover plate, and a protruding part 5 is provided on the lower surface of the disc 3, and one end of the support column 2 is fixedly connected with the bottom plate 1, and is arranged obliquely on the bottom plate 1 , the other end is movably connected with the protruding part 5 through a hinge 6, and the disc 3 can rotate along the vertical direction on the support column 2 through the hinge 6.

[0014] The support columns 2 are provided with several, and are arranged in parallel and evenly distributed in the transverse and longitudinal directions on the upper surface of the bottom plate 1, and the distance bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com