Printing head and image forming device

A printing head and printing element technology, applied in printing and other directions, can solve the problems of reduced printing quality, inability to stabilize the laminate structure, and component positioning, and achieve the effect that the printing quality will not be reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In this case, a dot-line printer as an image forming apparatus will be described.

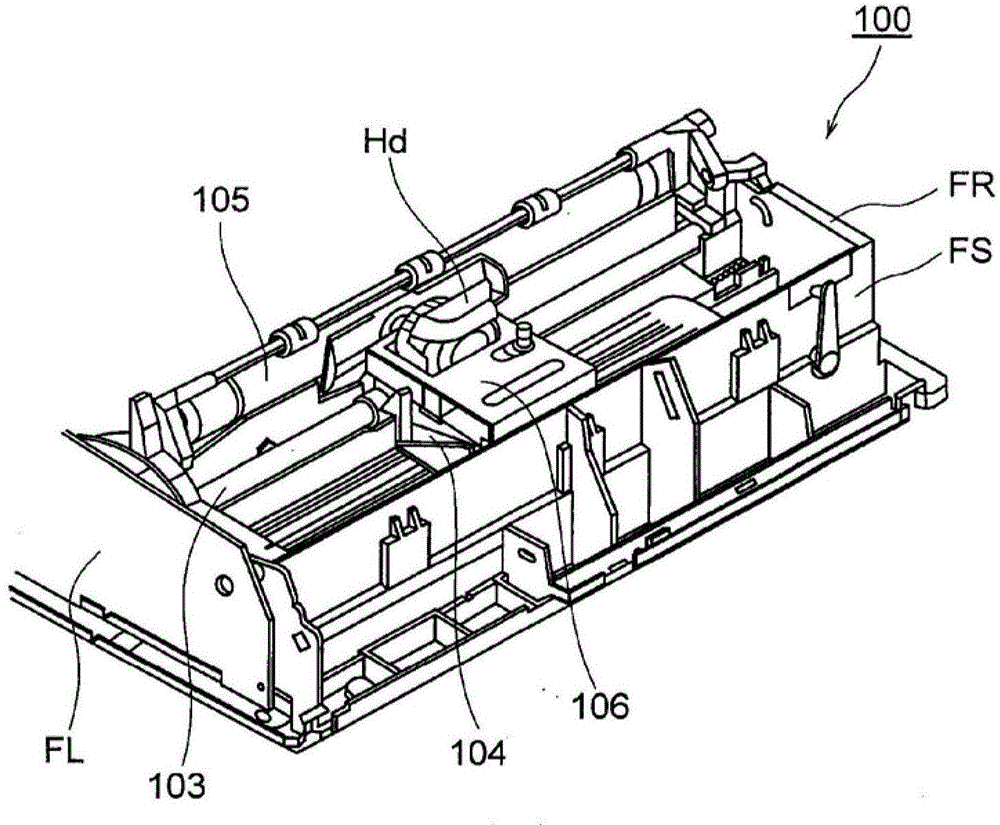

[0033] figure 2 It is a perspective view of the printer according to the embodiment of the present invention.

[0034] In the figure, reference numeral 100 denotes a printer (printing device), reference numerals FL and FR denote side frames serving as first and second frames disposed on the left and right sides of the printer 100, and reference numeral FS denotes side frames FL, FR, and A space frame serving as a third frame extending between the FRs, reference numeral 103 denotes a guide shaft extending between the side frames FL and FR and having a circular cross section, and reference numeral 104 denotes a space frame along the guide shaft 103. The carrier that moves (reciprocates) in the left-right direction of the printer 100, reference numeral Hd represents a swing type ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com