Strip casting installation and method for operating the same

A technology of equipment and direction of motion, applied in the field of operating belt casting equipment, can solve the problems of economic loss during downtime, continuous belt pollution, etc., to achieve the effect of improving product quality, improving economy, simplifying cleaning and/or polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

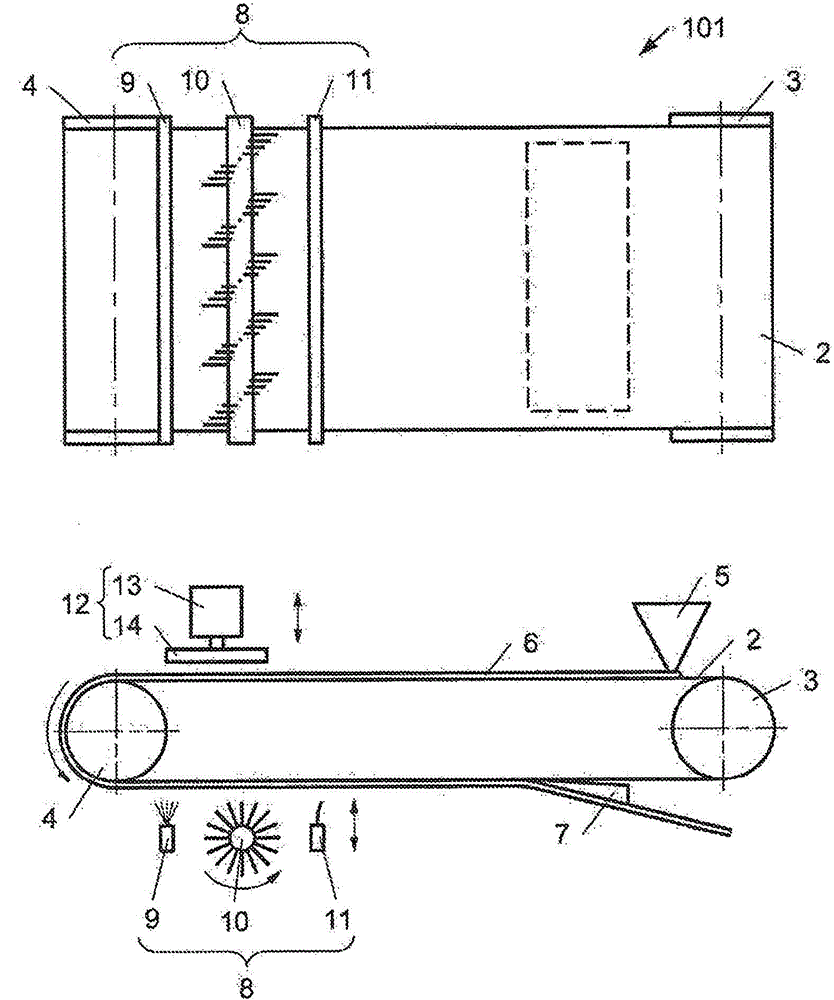

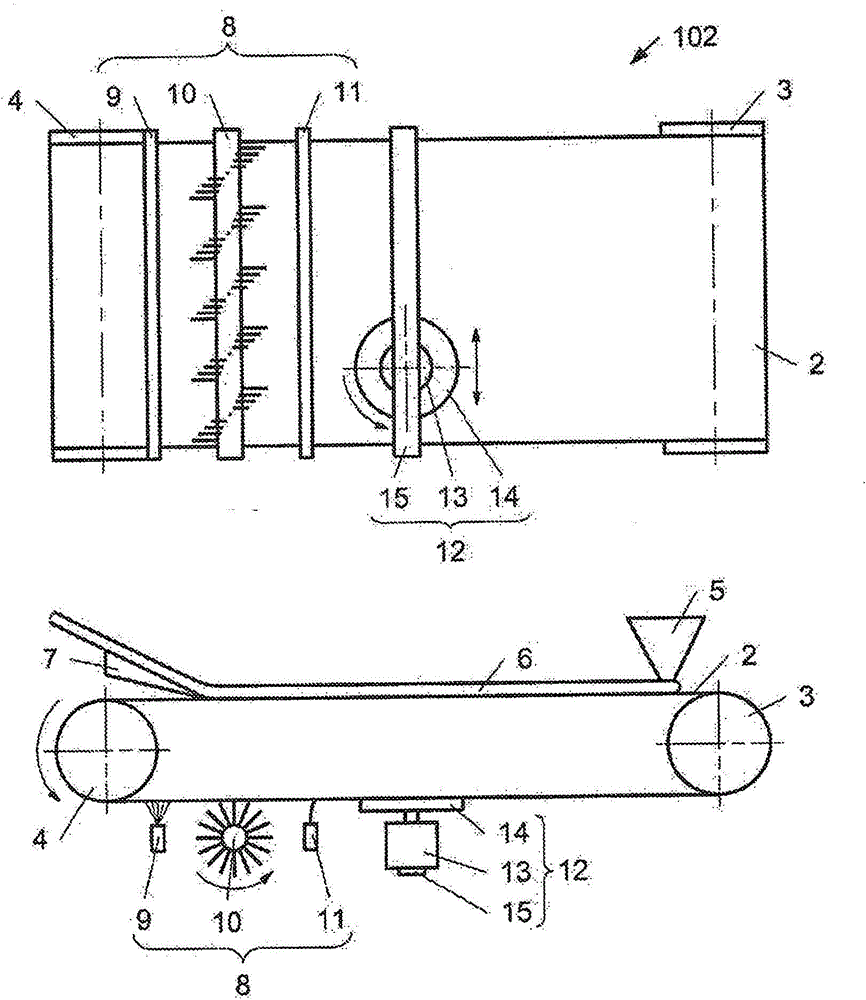

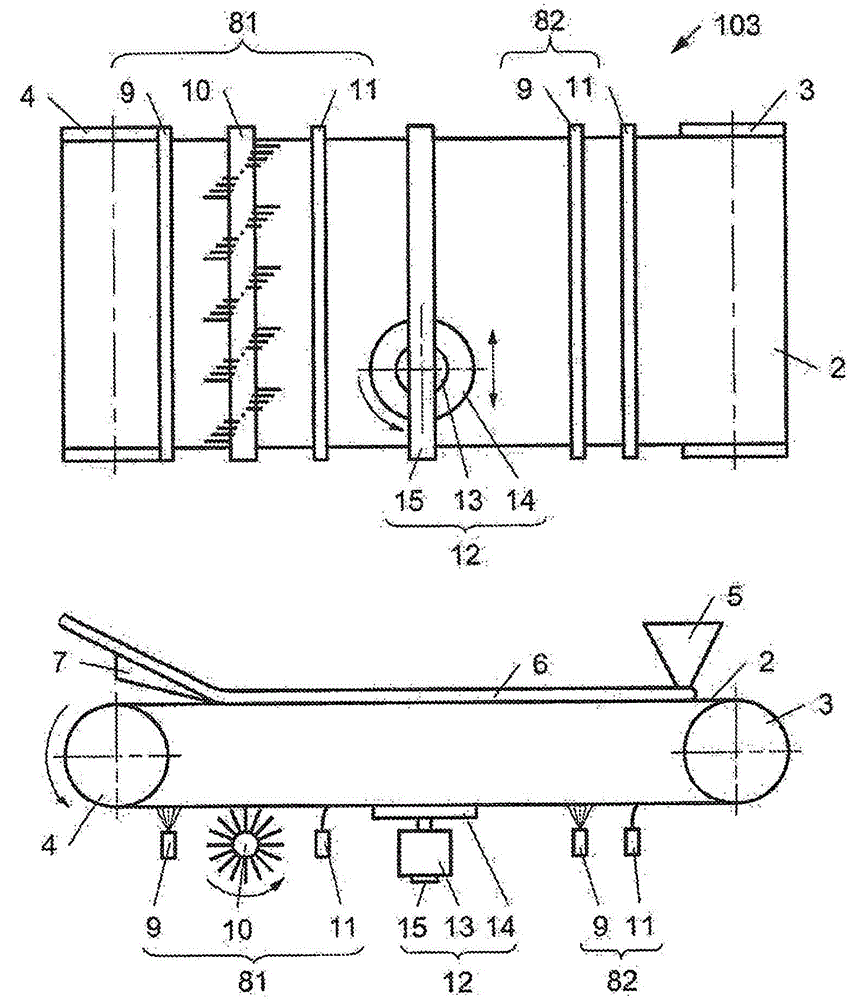

[0043] First of all, it should be pointed out that the same reference numerals or the same component names are used for the same components in different embodiments, and the disclosure contained in the entire specification can be reasonably transferred to those with the same reference numerals or the same component names. Parts. Similarly, the position descriptions selected in the description, such as upper, lower, side, etc., relate to the current description and the drawings shown, and are reasonably transferred to a new position when the position changes. In addition, individual features or combinations of features in the different embodiments shown and described are independent, inventive or solutions according to the present invention.

[0044] All descriptions about the numerical ranges in the specification can be understood as including any and all partial ranges. For example, descriptions 1 to 10 can be understood as including all partial ranges from the lower limit 1 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com