Small-resistance-value grounding grid of large device and design construction method

A large-scale equipment and grounding grid technology, applied in the direction of connection, connection contact material, electrical components, etc., can solve the problems of increasing construction difficulty, low soil resistivity, easy to collapse, etc., to avoid the increase of dosage and increase Conductive interface, the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Method embodiment 1, a method for designing and constructing a small-resistance grounding grid for large-scale equipment in a water-rich and high-water level area; including the following steps:

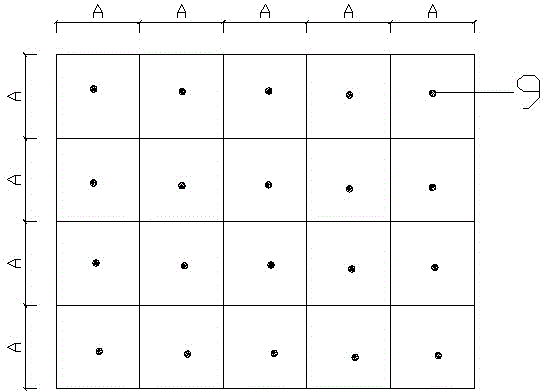

[0037] a. Determination of soil resistivity: figure 1 As shown, in the case of no rainfall and relatively dry weather within one week before the test, the grounding grid area is divided into grids with a side length A of 10×10 meters, and the soil is determined according to the four-line method after manual excavation to a depth of 1 meter. Resistivity test point 9, after using the ZC-8 grounding resistance tester to test the resistivity, take the maximum value as the design soil resistivity.

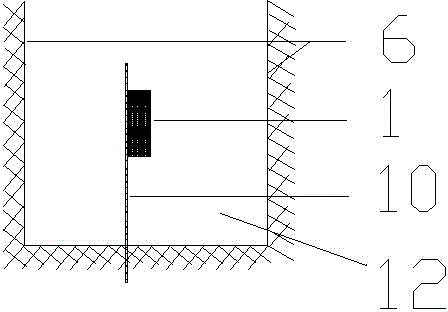

[0038] b. Determination of the burial depth of the horizontal grounding electrode and the vertical grounding electrode: the maximum thickness of frozen soil in winter, plus the optimal conductive distance of the soil, determines that the burial depth of the horizontal grounding electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com