Emptying valve with fast stop interlocking function

A vent valve and quick-break technology, applied in the direction of electric fluid pressure control, etc., can solve problems such as equipment bursting, economic losses, casualties, and operational errors, so as to achieve production safety, reduce the possibility of manual operation errors, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below with reference to the accompanying drawings.

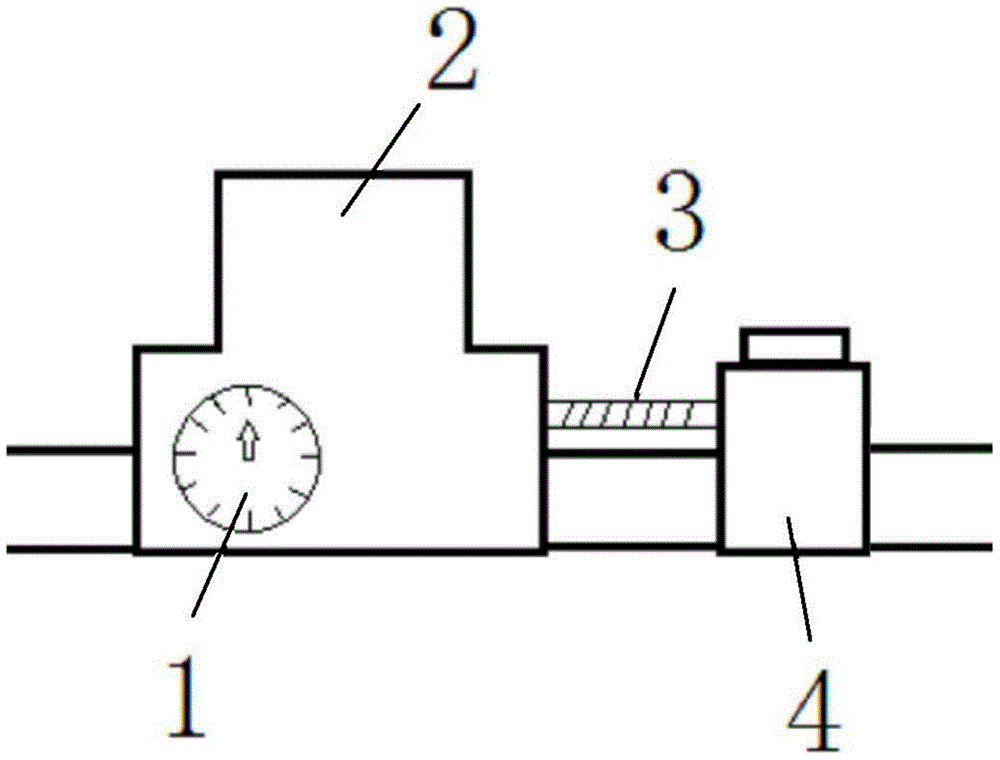

[0015] like figure 1 shown, the front view of the present invention. It is characterized in that it is composed of a pressure measuring device 1, a quick-break valve 2, a connector 3, and an interlocking vent valve 4. The pressure measuring device 1 is located at the connection between the quick-break valve 2 and the pipeline. The quick-break valve 2 is installed on the pipeline and is fixedly connected to the pipeline. One end of the connector 3 is connected to the quick-break valve 2, and the other end of the connector 3 is connected. One end is connected to the interlock vent valve 4, which is the switch of the pressure relief device.

[0016] The working process of this example: the pressure measuring device will automatically measure the internal pressure value of the equipment pipeline. When the pressure value reaches the set value, the quick-break valve will b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com