Optical sight orientation positioning fastener

A directional positioning and sighting technology, applied in weapon accessories, offensive equipment, etc., can solve the problems of small activity space, ineffective compatibility, aiming deviation, etc., to achieve the effect of stable connection, avoiding shooting deviation and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

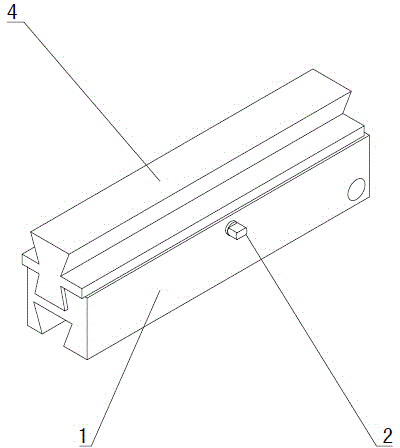

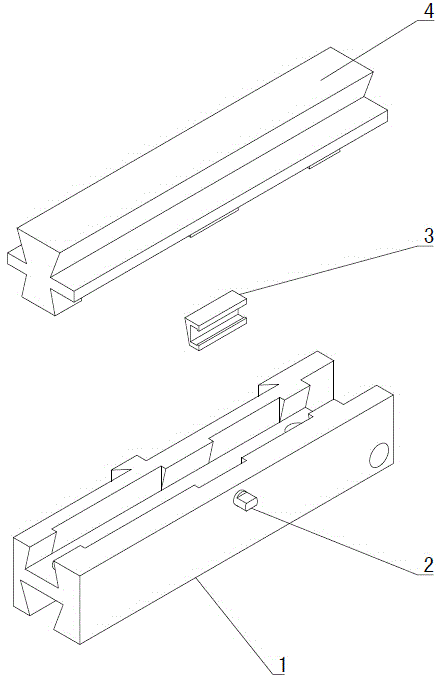

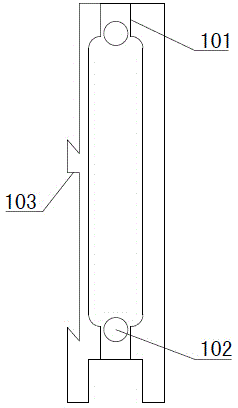

[0030] Figure 1~9 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~9 The present invention will be further described.

[0031] A scope directional positioning fastener, comprising a fixed base 1 and a scope fixed base 4, the lower part of the fixed base 1 is provided with an installation part for fixed connection with firearms, the upper part of the fixed base 1 is provided with a longitudinal chute 104, and the scope is fixed The lower part of the seat 4 is installed in the chute 104, and the fixed base 1 is provided with a horizontal fastening mechanism for horizontally fastening the scope fixed seat 4, and the same side of the scope fixed seat 4 and the fixed base 1 are provided with a mutual clamp The directional positioning mechanism, the scope fixed seat 4 top is provided with the scope fixing part 403 of fixing scope. The scope directional positioning fastener of the present invention installs the scope on the firearm t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com