Gear shifting control system

A technology of control system and controller, applied in the direction of transmission control, components with teeth, belt/chain/gear, etc., can solve problems such as poor comfort, large impact, and damage to the gearbox

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained in conjunction with specific drawings.

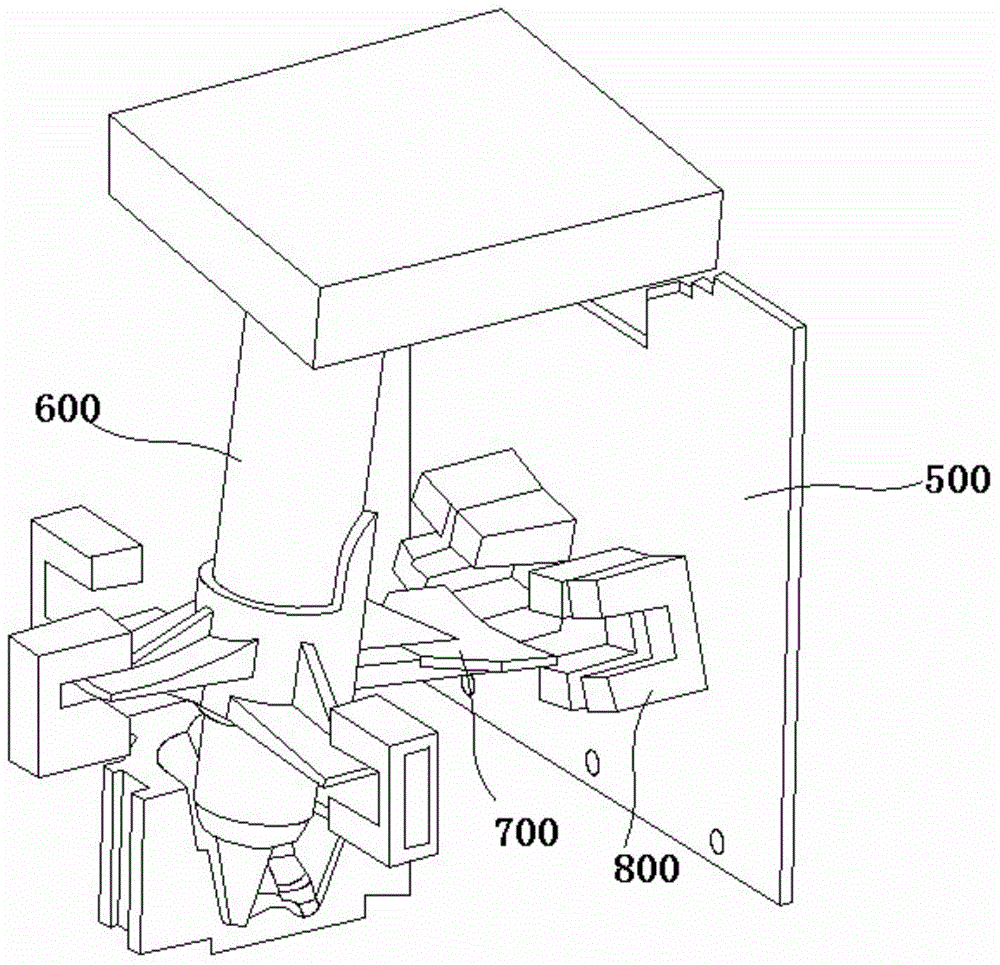

[0020] Reference figure 1 , Shift control system, including:

[0021] A shift controller 100 is connected to the vehicle communication network to provide a platform for input / output signal processing,

[0022] A shift handle, the lower end of the shift handle is provided with a photocell array device, the photocell array device collects user handle operation information, when the user operates the shift handle, the flying wing at the bottom of the shift handle can shield different photoelectric Control, distinguish the user’s specific shift request,

[0023] A shift actuator 200 includes a driving stepper motor and a three link connected with the driving stepper motor. The three link is connected to the shaft in the gearbox. Once the shift actuator receives the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com