A method for preparing high-purity 1-pentene

A technology of pentene and isopentene, applied in the field of high-purity 1-pentene, can solve the problems of many equipments, complicated processes and high process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] Embodiment [1-10]

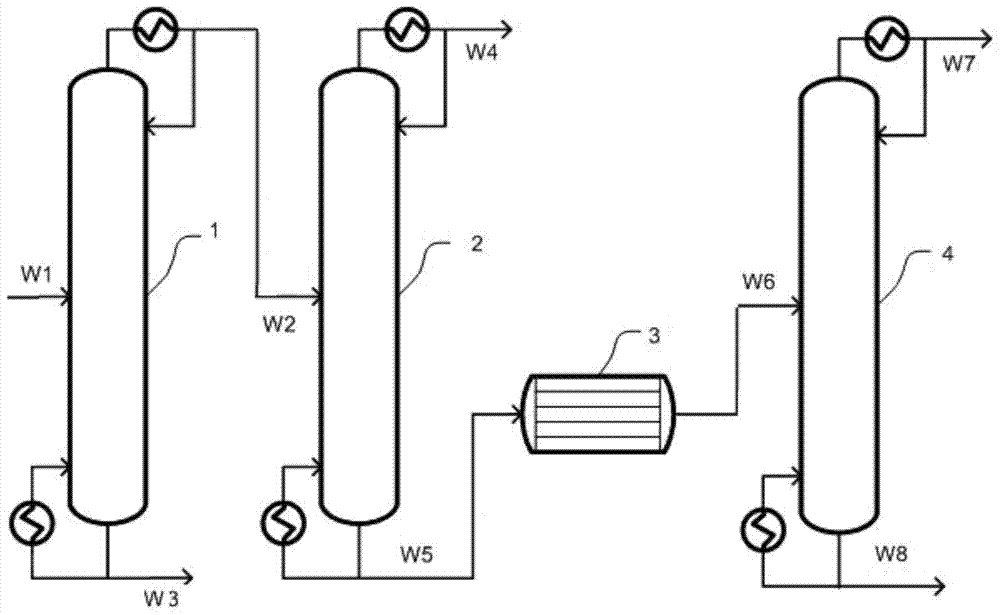

[0021] The process flow of Examples 1-10 is shown in the accompanying drawings. The raw material raffinate C5 fraction W1 is a petroleum petroleum C5 fraction from which diolefins and isopentene have been extracted and separated, and its main composition is shown in Table 1.

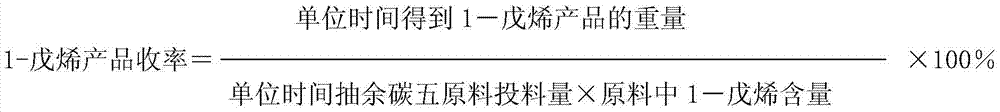

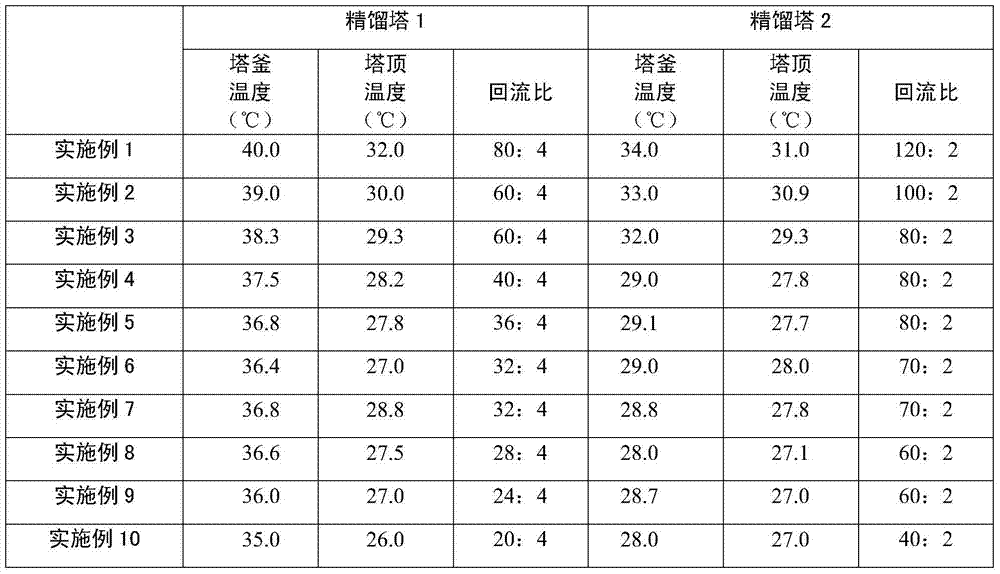

[0022] The process operating conditions of the rectifying towers 1, 2 and 4 of each embodiment, and the process operating conditions of the etherification reactor 3 are shown in Tables 2 and 3 respectively. The composition of material W7 was analyzed by gas chromatography, and the yield of 1-pentene was calculated in combination with the flow rate of each material. The results are shown in Table 4.

[0023] Table 1.

[0024] components

Content (weight%)

16.58

1,4 Pentadiene

0.26

1-pentene

9.34

2-Methyl-1-butene

0.63

n-pentane

55.95

2-pentene

13.01

2-Methyl-2-butene

3.95

margin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com