Automatic inner hole surfacing head

A welding head and inner hole technology, which is applied to welding equipment, welding equipment, arc welding equipment, etc., can solve the problems of difficult operation, long surfacing welding time, glare of arc light, etc., to ensure welding quality, convenient operation, and processing The effect of uniform balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

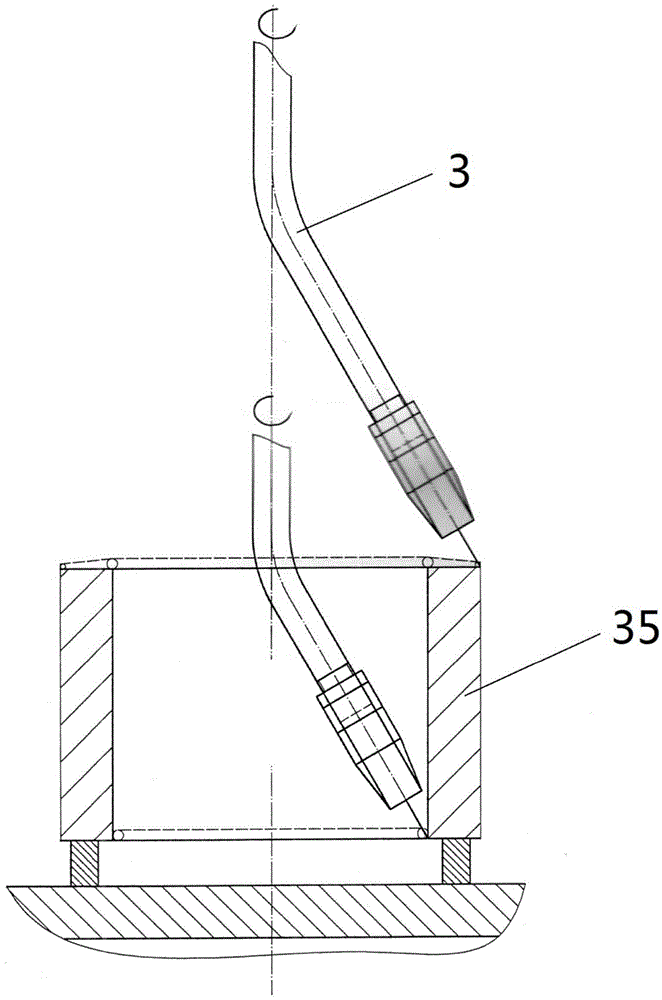

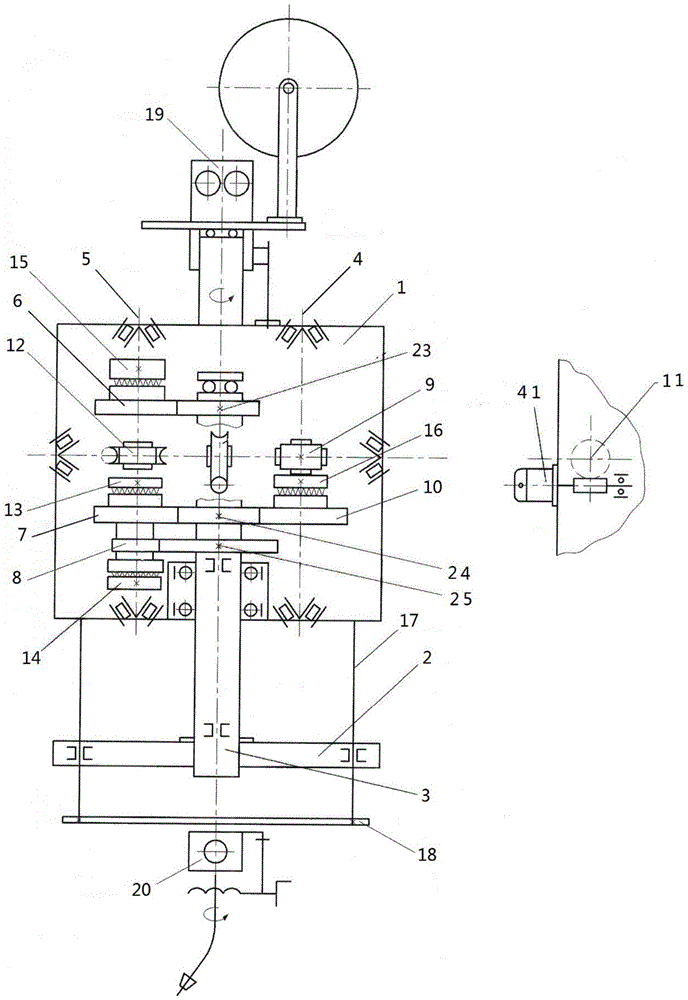

[0031] The invention discloses an automatic inner hole surfacing welding machine head, figure 1 It is a schematic diagram of "one knife drop" of the inner hole and the end face of the surfacing welding. In terms of practicability, the workpiece 35 is mounted on the platform and does not move. This saves the turntable and the transmission device, and the welding torch is lifted, rotated or translated to complete the surfacing welding. arc or plane. Use horizontal welding and vertical pile to achieve the flatness of the weld meat, and use a certain proportion of spiral to achieve a tight arc surface. Welding speed is used to control weld thickness, using diameter When the welding wire is used, the thickness of the welding meat can reach 10mm, and the welding plane can be selected in two forms: manual and automatic.

[0032] In general inner hole surfacing welding, the welding torch 3 rotates and spirals up at the same time. This method is called spiral horizontal welding (suc...

Embodiment 2

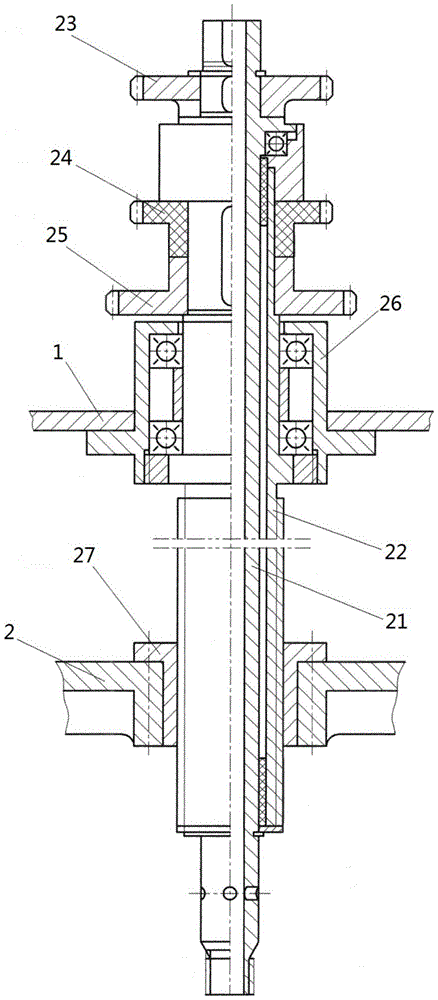

[0044] Such as Figure 4 and Figure 5 Shown is another implementation of the present invention. Including welding torch rotating assembly 33, welding torch lifting assembly 34, lifting screw rod 22, welding torch rotating rod 21, lifting nut 27, lifting driven wheel 31, hand bevel gear 30, lifting nut seat 27, lower positioning sleeve 29, upper positioning Cover 32, welding frame assembly 20.

[0045] A welding torch rotating gear 37 is arranged on the welding torch rotating rod 21, and the welding torch rotating gear 37 is driven by a motor and other transmission mechanisms. The lifting screw mandrel 22 is threadedly matched with the lifting nut 27, and the lifting nut 27 is fixedly connected with the lifting driven wheel 31 and the hand bevel gear 30, and the lifting driven wheel 31 can be driven by a motor and a transmission structure.

[0046] The nut drive does not need a drag plate and a fixed transmission box. The rotation of the lifting nut makes the lifting screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com