A motor differential protection system and method

A technology of differential protection and electric motors, which is applied in the direction of emergency protection circuit devices and electrical components, etc., can solve the problems of quick action and reliability reduction of differential protection, improve the anti-misoperation ability, reduce unbalanced current, The effect of lowering the start-up current threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

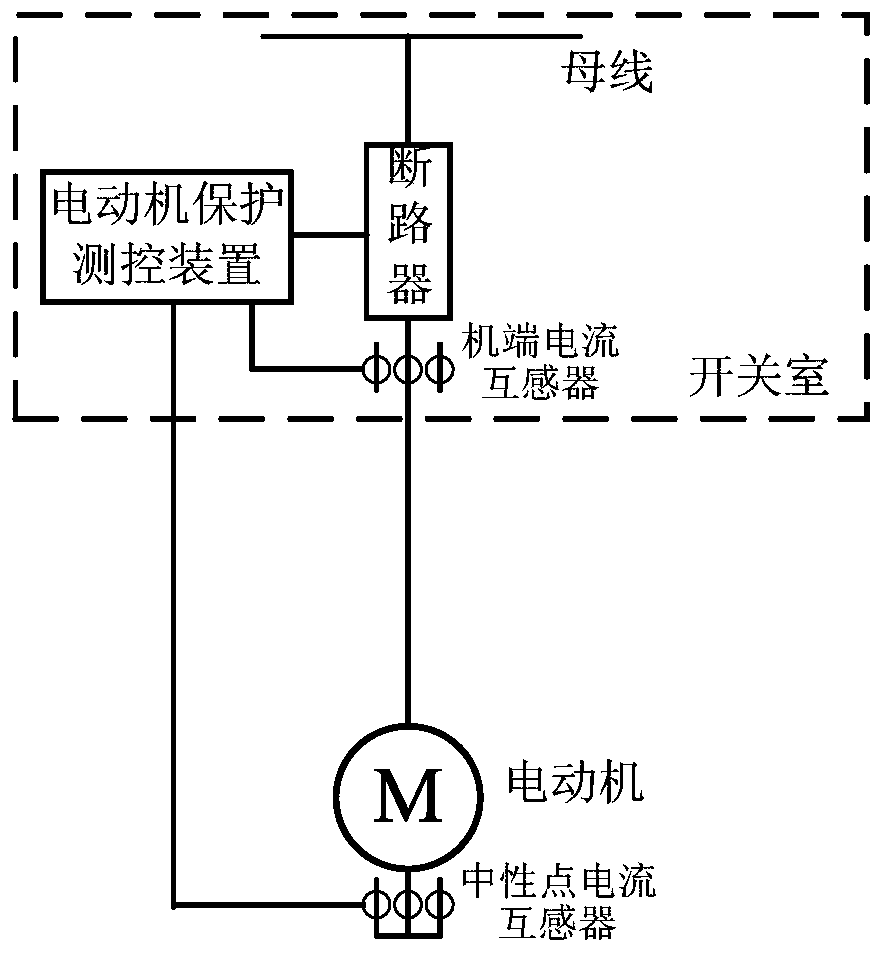

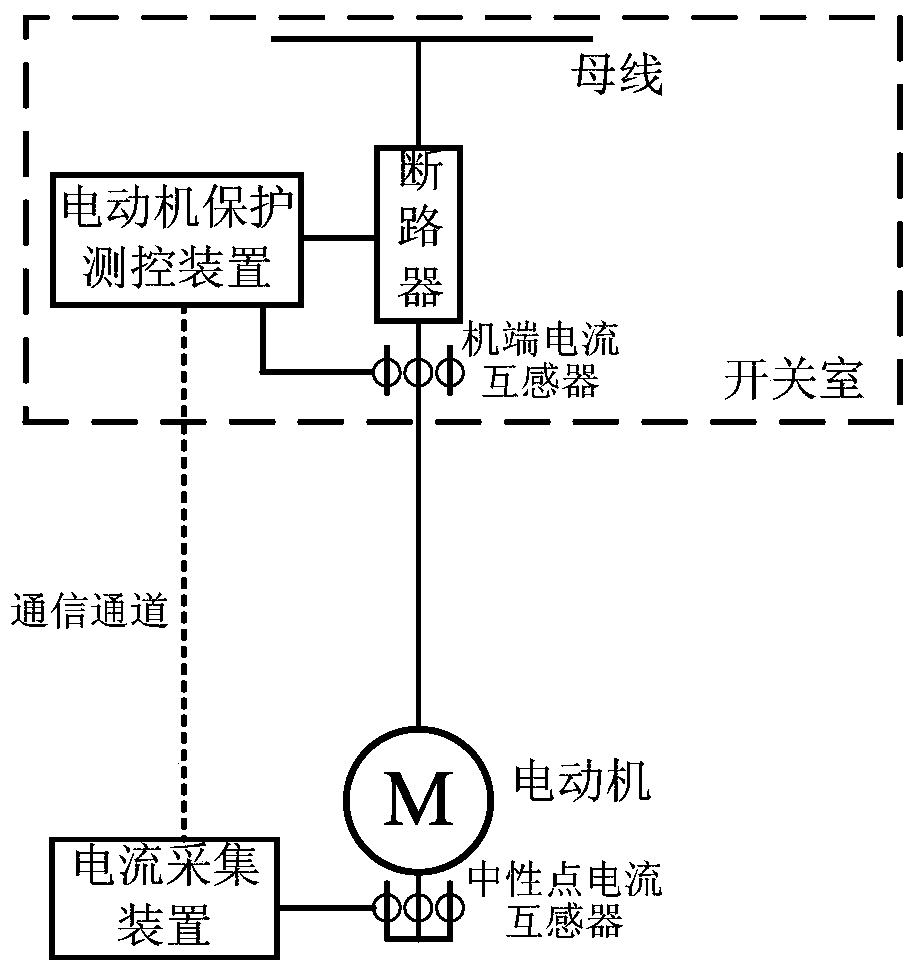

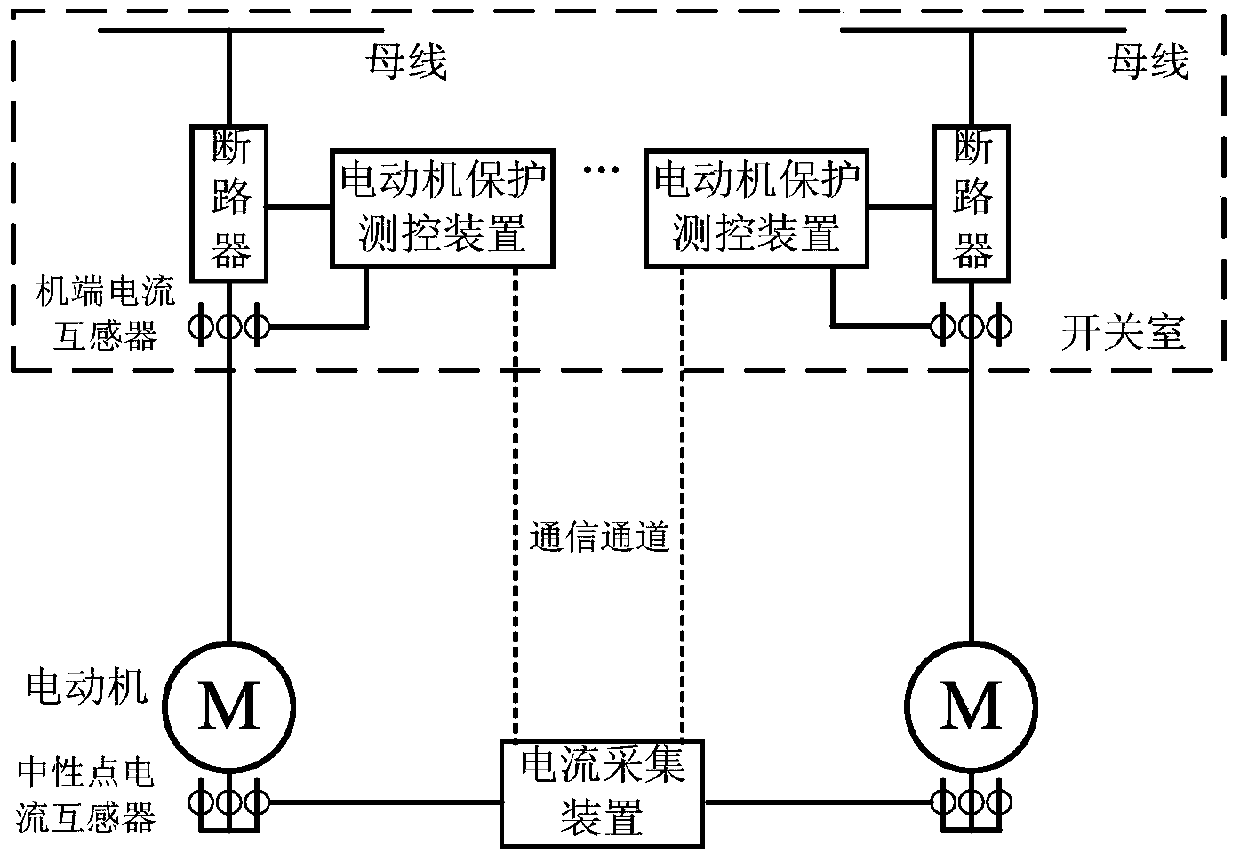

[0029] The invention provides a motor differential protection system, which is aimed at a motor that needs to be equipped with differential protection. Cooperate figure 2 As shown, the number of motor protection devices and circuit breakers is the same and corresponds to each other. Each motor protection device is installed in the circuit breaker cabinet of the corresponding circuit breaker, and the voltage collection of the circuit breaker and the terminal current of the motor are completed through cables. Acquisition, acquisition of signals such as the position of the circuit breaker and control of the circuit breaker; the neutral point current of the motor used for differential protection is connected to the current acquisition device from the neutral point current transformer through the cable, and the current acquisition device converts the neutr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com