A series of multi-scale square rock structural surface friction angle measurement device and method

A measuring device and technology of structural planes, applied in the engineering field, can solve the problems of inability to test various series of scale structural planes, high accuracy of test results, and inability to fix the bottom plate, and achieve high accuracy of test results, easy operation, and difficulty in turning over and the like. The effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

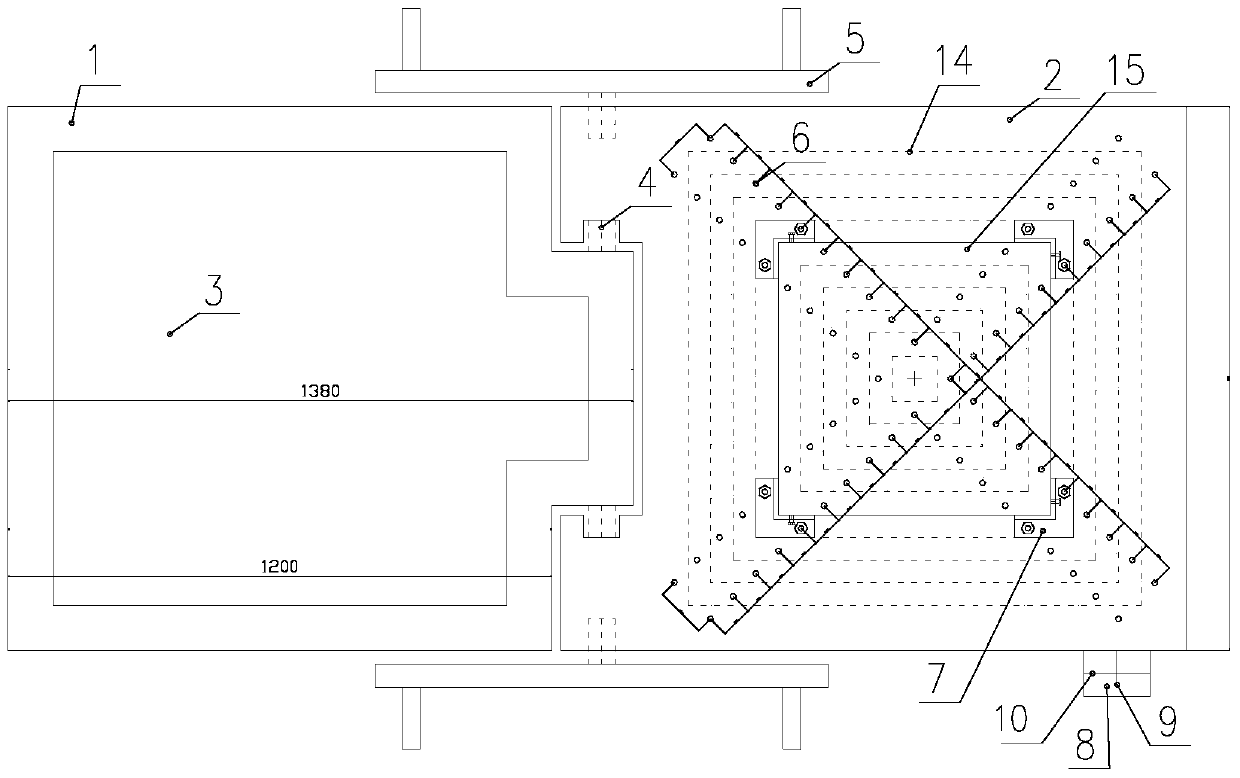

[0027] refer to Figure 1 ~ Figure 3 , a series of multi-scale square rock structural surface friction angle measuring devices, including a frame, a test platform and a fixed assembly 7 under the square rock structural surface, the test platform includes a turntable 2, and one side of the turntable 2 is fixedly installed On the rotating shaft 4, the rotating shaft 4 is rotatably set on the frame, the end of the rotating shaft 4 is linked with the rotating handle 5, and the upper surface of the rotating table 2 is provided with a sample positioning line and a center positioning line. point, the anchor point is the central point of the square rock structure surface, with the anchor point as the origin of the plane coordinate system, two rows of bolt holes 6 are respectively distributed along each diagonal of the square rock structure surface, and each row of bolt holes The adjacent bolt holes are arranged at equal intervals; the square rock structure surface lower wall fixing as...

Embodiment 2

[0032] refer to Figure 1 ~ Figure 3 A method for measuring the friction angle of a multi-scale square rock structural surface, comprising the following steps:

[0033] (a) select the rock face sample 15 of the size to be tested;

[0034] (b) Adjust the rotating handle 5 so that the rotating table 2 is placed flat on the operating table;

[0035] (c) Place the footwall structural surface of the square rock structural surface on the turntable 2 using the sample positioning line 14, requiring the center of the footwall structural surface to coincide with the positioning point of the turntable 2;

[0036] (d) Connect the bottom plate structure surface with the turntable 2 through the bottom bolts 11 of four right-angled fixing plates 13; connect the side bolts 12 of the right-angled fixing plates 13 through the threaded bolt holes until the end of the bolts In close contact with the sample of the structural surface of the lower wall;

[0037] (e) Place the structural surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com