Vertical axis wind power generation structure capable of achieving high power

A vertical-axis, high-power technology, applied in the field of vertical-axis wind power generation structure, can solve problems such as not too large blade size, lower available minimum wind speed, output power limitation, etc., achieve wide application scenarios, reduce available minimum wind speed, and increase output The effect of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

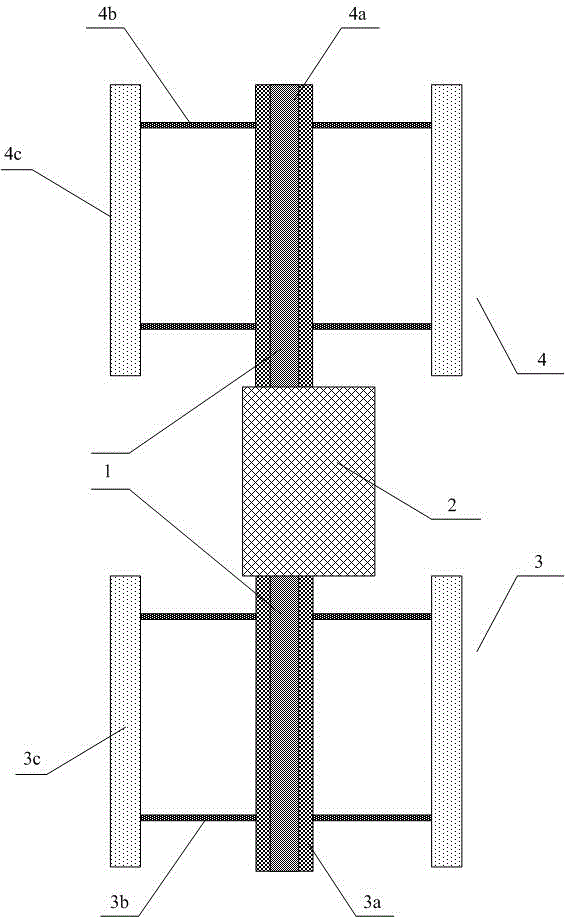

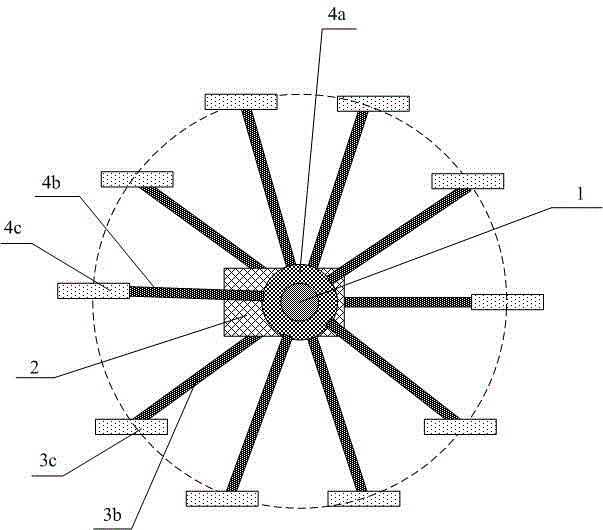

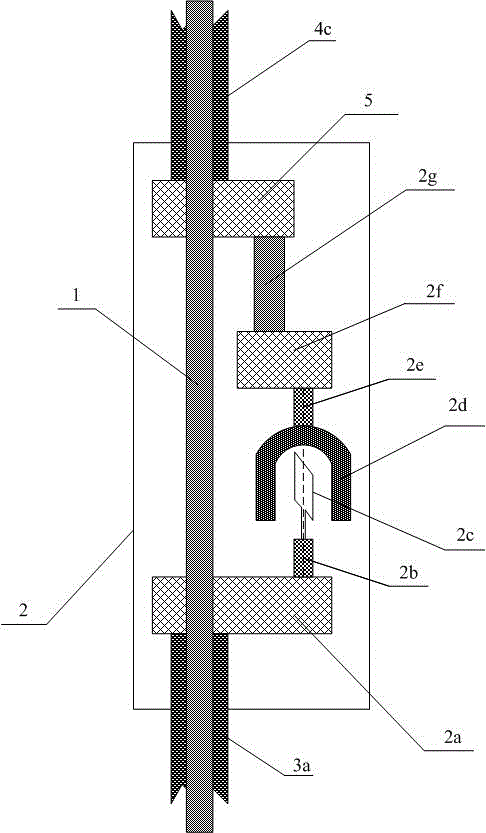

[0020] Embodiment one, figure 1 A structural diagram of the high-power vertical-axis wind power generation structure provided by this embodiment is shown, figure 2 It shows a top view of the high-power vertical-axis wind power generation structure provided by this embodiment, image 3 It shows the internal structural diagram of the generator cabin in the vertical axis wind power generation structure provided by this embodiment, Figure 4 A schematic structural diagram of an inverting box in a high-power vertical-axis wind power generation structure provided by this embodiment is shown. The high-power vertical-axis wind power generation structure includes a circular pillar 1 connected to the generator cabin 2 in the upper middle of the circular pillar 1, and is characterized in that it also includes: a lower wind rotor structure 3 and an upper wind rotor structure 4; The lower wind wheel structure 3 includes a first slow rotating shaft 3a, a first support wing 3b horizontall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com