Horizontal hole parts brush plating machine

A technology for parts and electric brush plating, applied in the field of electric brush plating machine tools for horizontal hole parts, can solve the problems of low efficiency, unstable modification quality, uneven brush plating, etc., achieve uniform brush plating, and prevent plating solution from splashing , The effect of saving plating solution

Active Publication Date: 2017-01-04

GUANGXI UNIV

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The purpose of the present invention is to provide a horizontal brush-plating machine tool for hole parts, so as to overcome the shortcomings of uneven brush-plating, low efficiency and unstable modification quality during manual brush-plating

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0026] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

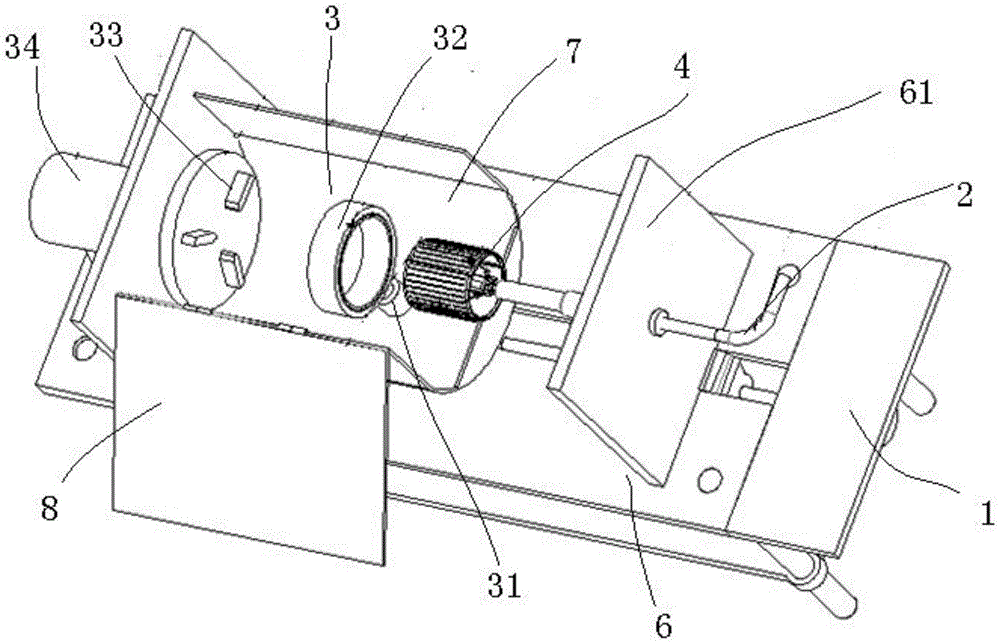

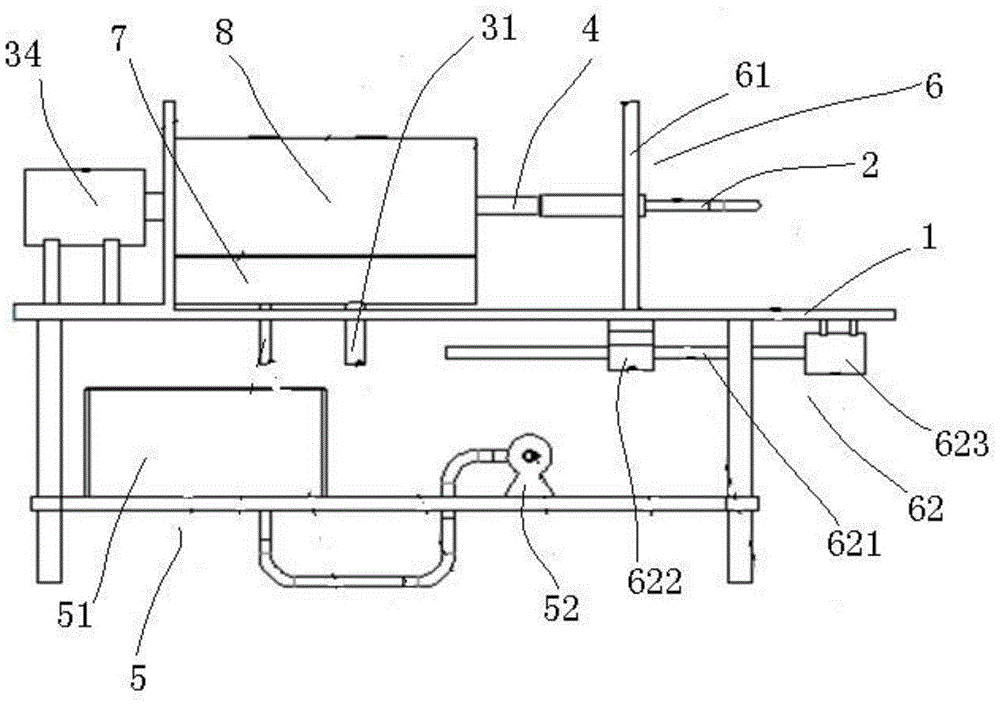

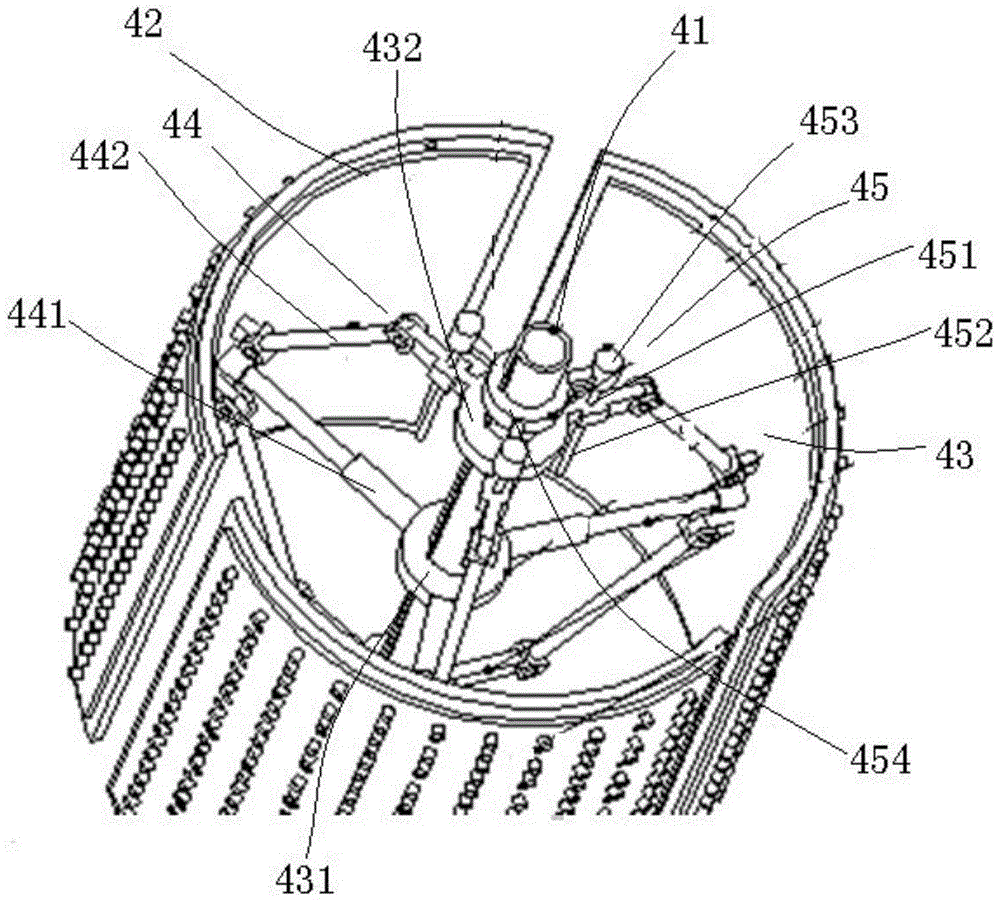

The invention discloses a horizontal type hole part brushing electroplating machine tool. The horizontal type hole part brushing electroplating machine tool comprises a worktable, an infusion pipe, a workpiece fixing device and a plating pen which corresponds to a workpiece, wherein the plating pen comprises a pipe shaft and plating pen brushes; the pipe shaft is connected with the infusion pipe; each plating pen brush is in a circular arc plate shape and is in a hollow structure; bristles, a liquid spraying opening and a pressure sensor are arranged on the outer wall surface of each plating pen brush; and the plurality of plating pen brushes are uniformly erected on the pipe shaft through a diameter changing mechanism along the circumferential direction. According to the horizontal type hole part brushing electroplating machine tool, the plating pen with the adjustable brushing plating diameter can be used for repairing cylindrical parts with different shaft diameters; a plating plate of the plating pen is in a hollow structure and can be used for storing plating liquid; and the plating liquid is uniformly sprayed by plating liquid holes so that the flowing plating is more uniform and the plating liquid can be saved. The clamped workpiece is supported by a bearing so that the outer diameters of the workpiece and the plating pen keep better coaxiality so that the brushing plating is more uniform and deviated brushing is not caused.

Description

technical field [0001] The invention relates to the field of electric brush plating, in particular to a horizontal brush plating machine tool for hole parts. Background technique [0002] Brush plating is a surface processing technology that uses electrochemical methods to reduce metal ions to metal and deposit them on the surface of metal or non-metal products to form a smooth and dense metal coating that meets the requirements. With the development of science and technology and production, brush plating technology involves more and more fields, and people's requirements for coating are getting higher and higher. At present, the application of metal coating has spread all over the various production and research departments of economic activities, and has great significance in production practice. However, the brush plating technology still mainly stays in the stage of manual brush plating in specific applications, which has the disadvantages of high labor intensity, low e...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C25D5/06C25D7/04

CPCC25D5/06C25D7/04

Inventor 黄伟辛小刚段月星张章徐敏敏王永康张亚丽

Owner GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com