Ellipse superposition solid-liquid separation apparatus

A solid-liquid separation and elliptical stacking technology, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of long equipment length, inconvenient use, and leakage of solid objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

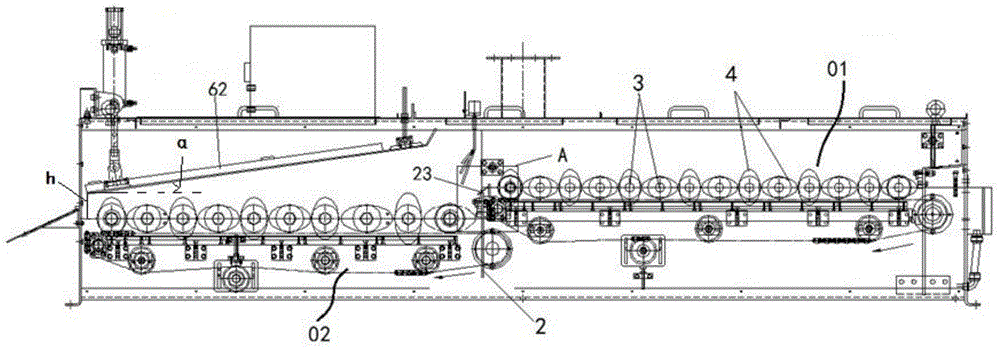

[0062]This embodiment provides an elliptical solid-liquid separation device, such as Figure 1-2 As shown, it includes a natural dehydration section 01 for carrying and transporting the processed objects and gradually realizing the natural dehydration of the processed objects in the process, and receiving the processed objects after natural dehydration in the natural dehydration section 01 and using a press The plate 62 further squeezes and dehydrates the treated material and then discharges it into the pressing and dehydrating section 02 .

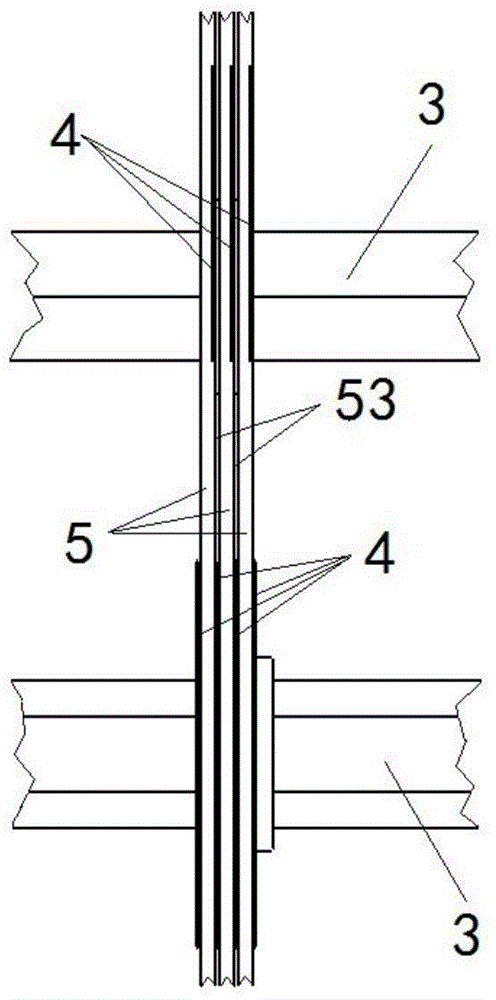

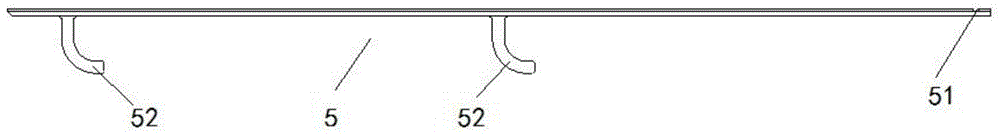

[0063] Both the natural dehydration section 01 and the press dehydration section 02 include a plurality of rotary shafts 3 that are distributed side by side along the conveying direction of the treated material and can rotate around their own axes at the same speed and at the same speed under the drive of the driving member. A number of rotary plates 4 arranged on the rotary shaft 3, a plurality of rotary plates 4 fixedly sleeved on the s...

Embodiment 2

[0072] This embodiment provides an elliptical solid-liquid separation device, which is a deformation based on Embodiment 1, the difference is that:

[0073] In this embodiment, the ratio of the total area of all drainage gaps 53 used for drainage on the carrying surface of the natural dehydration section to the total area of the carrying surface of the natural dehydration section is 2:10. The ratio of the total area of all drainage gaps 53 for drainage to the total area of the carrying surface of the press dehydration section is 1:13, the ratio of the length of the natural dehydration section 01 to the length of the press dehydration section 02 is 1.5:1, and the length of the natural dehydration section 01 2m and 1m in width; the speed at which the natural dehydration section 01 transports the treated matter is equal to the speed at which the pressed dehydration section 02 transports the treated matter and both are 0.2m / s.

[0074] Set the pressing plate 62 to the oppo...

Embodiment 3

[0077] This embodiment provides an elliptical solid-liquid separation device, which is a deformation based on Embodiment 1, the difference is that:

[0078] In this embodiment, the ratio of the total area of all drainage gaps 53 used for drainage on the carrying surface of the natural dehydration section to the total area of the carrying surface of the natural dehydration section is 3:10. The ratio of the total area of all drainage gaps 53 for drainage to the total area of the carrying surface of the press dehydration section is 1:11, the ratio of the length of the natural dehydration section 01 to the length of the press dehydration section 02 is 2:1, and the length of the natural dehydration section 01 The length is 2.5m, and the width is 1m; the speed of conveying processed objects in natural dehydration section 01 is 0.1m / s, and the speed of conveying processed objects in press dehydration section 02 is 0.2m / s.

[0079] Set the pressing plate 62 to the opposite dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com