Pole ear folding and rubberizing system of automatic packing machine

An automatic packaging machine and pole ear technology, applied in packaging machines, packaging, transportation and packaging, etc., can solve the problems of low production efficiency, poor product consistency, affecting battery reliability and aesthetics, and improve production efficiency and reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

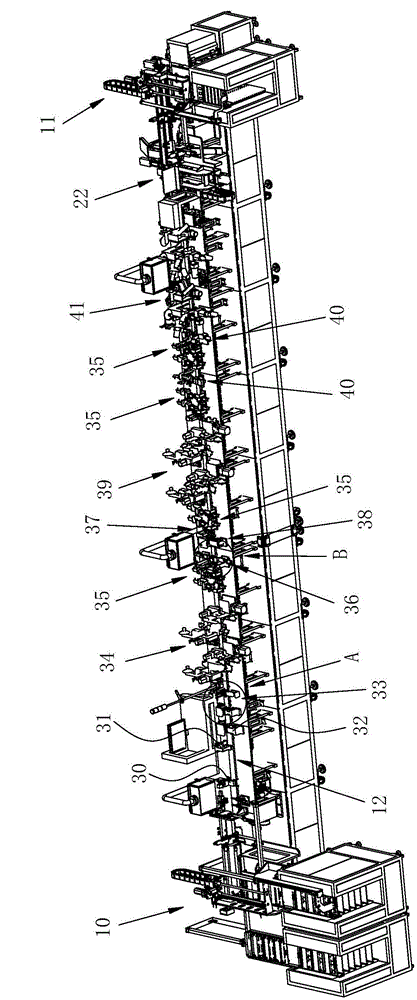

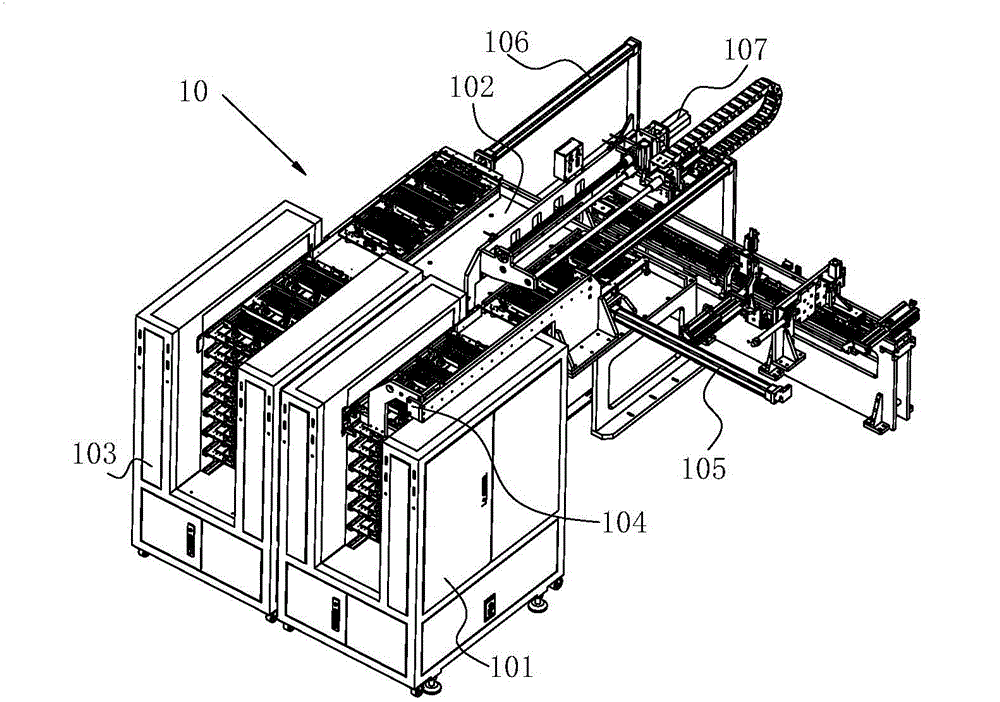

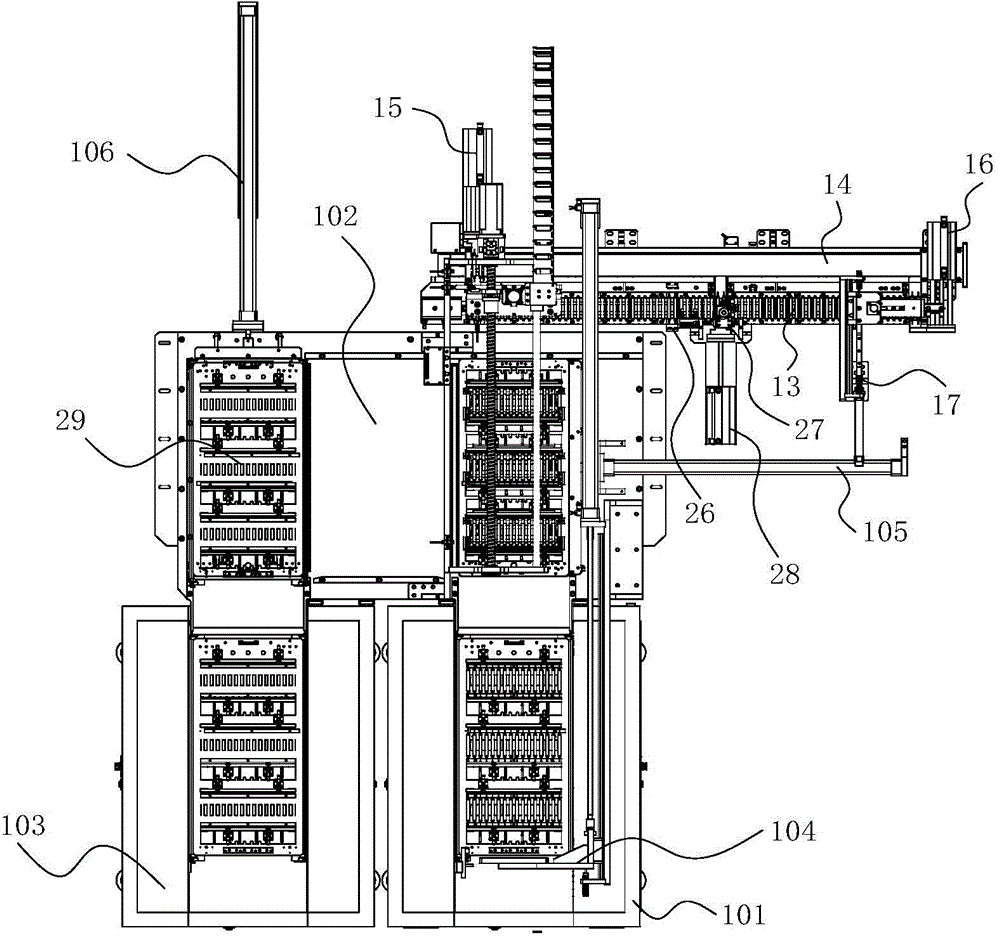

[0063] Such as figure 1 As shown, an automatic packaging machine includes a feeding system 10 and an unloading system 11, and an operation conveying line 12 for conveying batteries between the feeding system 10 and the unloading system 11, and the automatic packaging machine is conveyed along the operation In the forward direction of the line 12, there are sequentially provided a battery counter 30 for counting the number of batteries, a centering mechanism 31 for placing the batteries in the center, a tab flattening mechanism 32 for pressing the battery tabs to a horizontal position, and a tab changer. Orientation device 33 , right-angle gluing device 34 , tab adjusting device 36 , tab folding device, door-shaped gluing device 39 , two tab super-edge scraping devices 40 and cylindrical roll-up devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com