Spray method for controlling spray robot

A spraying robot and robot technology, applied in spraying devices and other directions, can solve the problems of complex offline programming software for robots, simulate spraying paths, and lack of plate workpieces, and achieve the effects of reducing human burden, improving spraying accuracy and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] A detailed description will be given below of embodiments of the present invention. Although the present invention will be described and illustrated in conjunction with some specific embodiments, it should be noted that the present invention is not limited to these embodiments. On the contrary, any modification or equivalent replacement made to the present invention shall be included in the scope of the claims of the present invention.

[0052] In addition, in order to better illustrate the present invention, numerous specific details are given in the specific embodiments below. It will be understood by those skilled in the art that the present invention may be practiced without these specific details. In other instances, well-known methods, processes, components and circuits are not described in detail so as to highlight the gist of the present invention.

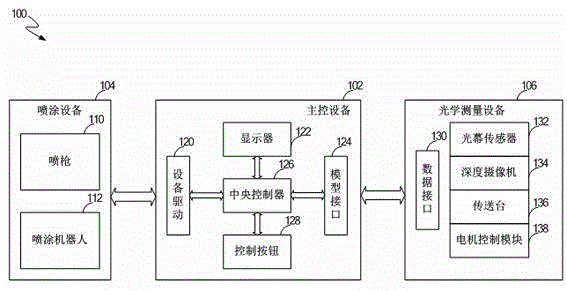

[0053] figure 1Shown is an intelligent robotic painting system 100 according to an embodiment of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com