Tower crane slewing bearing washer spraying protective device

A technology of tower cranes and slewing bearings, applied in the direction of spraying devices, etc., can solve the problems of taking a long time, limiting the progress of paint spraying and assembly, and not being able to stick stickers, so as to achieve convenient and quick installation and removal, and improve the efficiency of spraying and assembly , good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

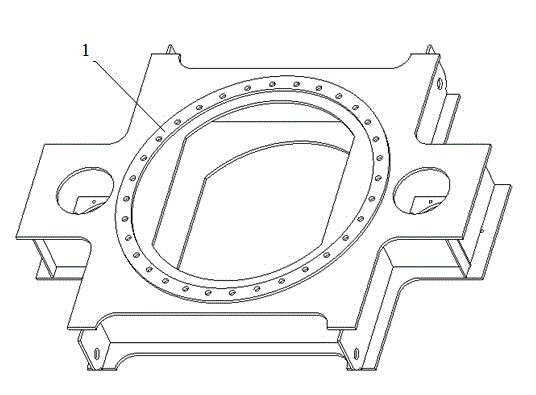

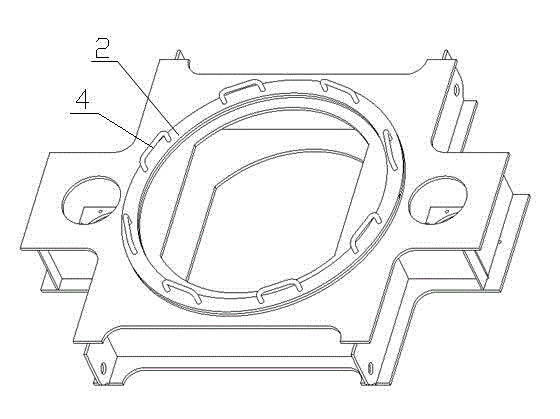

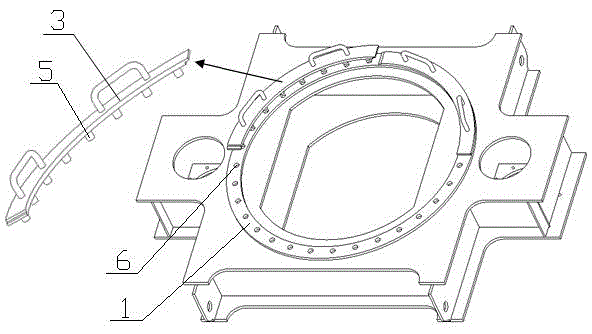

[0023] Such as figure 2 and image 3 As shown, the present invention includes four protective blocks 3, which are made of rubber and have the same structure, and are assembled into a ring together. The top surface of each protective block 3 is symmetrically provided with two handles 4, the bottom surface is evenly distributed with cylinders 5, and the front end of the cylinder 5 is provided with chamfers, and the number and position of the cylinders 5 are consistent with the bolts on the slewing bearing washer 1. The mounting holes 6 are in one-to-one correspondence and are interference fit. The two ends of the protective block 3 are provided with opposite step structures, so that two adjacent protective blocks 3 can cooperate end to end.

[0024] Before the upper and lower supports are sprayed, install a set of protective device 2 made of rubber on the slewing bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com