Ultrasonic detection analysis method for defect type of laser cladding remanufactured component

A laser cladding and defect-type technology, applied in the field of measurement, can solve the problems of relying on the experience of inspectors, technical level, understanding of manufacturing process, strong limitations, etc., and achieve the effect of avoiding hidden dangers of quality and safety, waste of resources, and low technical level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

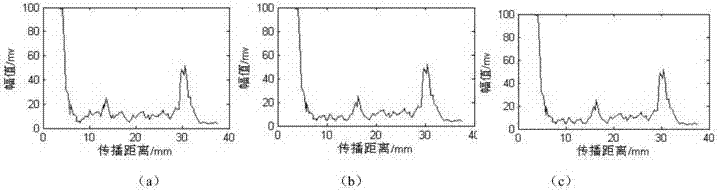

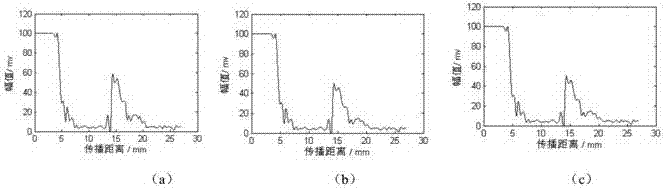

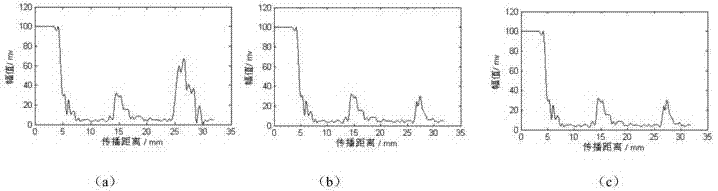

[0037]For laser cladding remanufactured parts, stress and its damage are the most fundamental reasons affecting its quality, but the direct cause of part quality failure is defects, because dangerous defects in parts (such as extended cracks) usually cause stress Therefore, it is the key to ensure the quality and performance of such products to realize the defect detection and type judgment of laser cladding remanufactured parts. Common defects in laser cladding remanufactured parts mainly include pores, cracks, and inclusions. Numerical simulation results show that the characteristics of the scattering wave field of different types of defects are obviously different, such as the type of waveform, energy distribution, and propagation direction. And when the propagation direction of the ultrasonic wave changes, the scattering wave field change...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com