An automatic measuring device for the length of sleeve parts

An automatic measurement and sleeve technology, applied in the direction of measurement devices, instruments, etc., can solve the problems of high precision requirements of transmission devices, inability to realize automation, and complex control systems of measurement devices, so as to ensure smooth progress and measurement accuracy, improve Measurement automation, stable and reliable measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

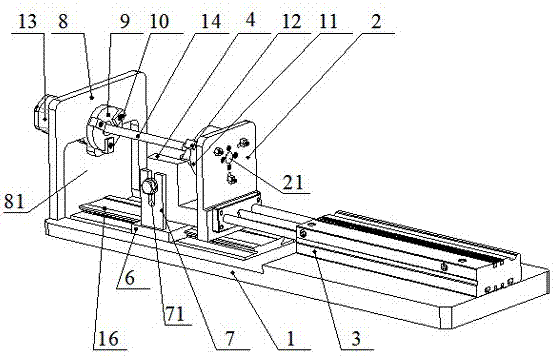

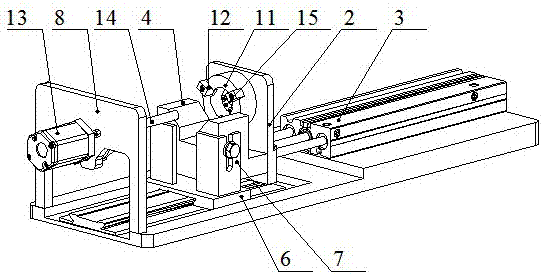

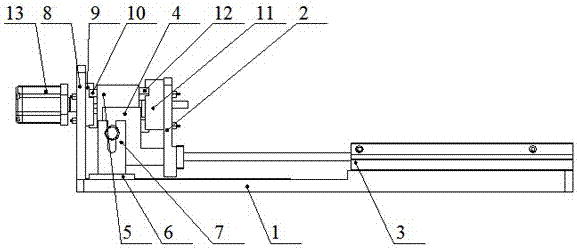

[0030] see Figure 1 to Figure 3 , The automatic measuring device for the length of sleeve parts of the present invention includes: a clamping mechanism, a positioning mechanism and a measuring mechanism. Wherein, the clamping mechanism includes: base plate 1, push plate 2, cylinder 3 and V-shaped block 4, push plate 2 is connected on the piston rod of cylinder 3, V-shaped block 4 is fixedly connected on the push plate 2 for supporting and limiting Position the workpiece 5 to be measured, and the cylinder 3 drives the push plate 2 to drive the V-shaped block 4 to move. As an improvement, the clamping mechanism also includes a slide table 6 that is slidably connected to the bottom plate 1. A pair of L-shaped plates 7 are fixed on the slide table 6. U-shaped holes 71 are formed on the L-shaped plates 7 to fix the V-shaped plate. block 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com