Flexible shearing device

A shearing device and flexible technology, applied in the direction of shearing devices, shearing machine accessories, shearing machine equipment, etc., can solve problems such as excessive gaps, achieve the effect of reducing maintenance costs and improving quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, the present invention will be described in detail by using figures and words.

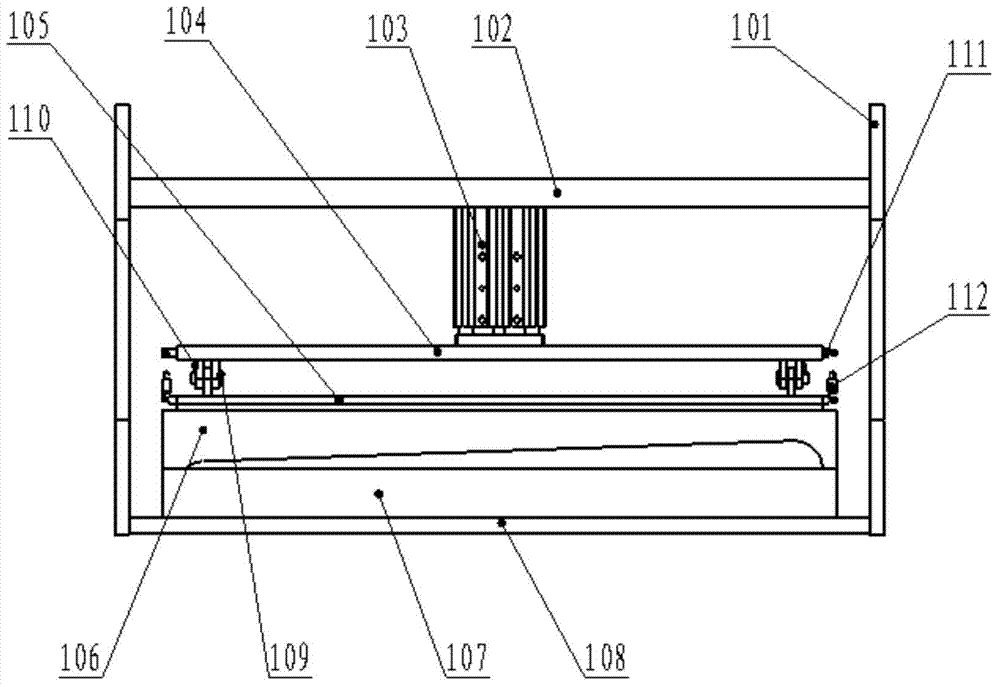

[0021] The invention provides a flexible shearing device, such as figure 1 and figure 2 As shown, it includes a fixed bracket 101, and the fixed bracket 101 is provided with an upper support plate 102 and a lower support plate 108 arranged longitudinally, and the lower support plate 108 is provided with a fixed blade 107, wherein the upper support plate 102 and the lower support plate 108 are provided with There is an adjustment space between the lower support plates 108, a flexible shear mechanism is arranged in the adjustment space, the upper support plate 102 is connected with a movable knife 105 through the flexible shear mechanism, and the movable knife 105 is provided with an upper blade 106, and the flexible shearing mechanism adjusts the upper blade 106 to always maintain elastic contact with the fixed blade 107, and the flexible shearing mechanism can be realized by e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com