Unmanned roadway driving and anchoring all-in-one machine

An all-in-one machine and roadway technology, used in tunnels, installation of bolts, temporary shields, etc., can solve the problems of low safety factor, work efficiency and operation simplicity are not as good as adopted, not flexible enough, etc., to achieve flexible cutting, supporting The effect of stable and continuous protection and increased adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

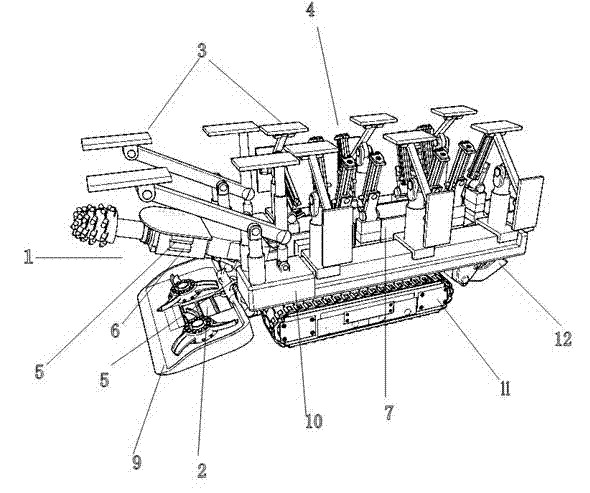

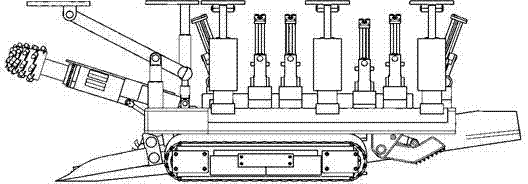

[0024] see Figure 1 to Figure 5 , an unmanned roadway digging and anchoring integrated machine in the figure, including: a tunneling system 1, a conveying system 2, a temporary support system 3, an anchoring system 4, a tunneling machine water system 5, a sensor system 6, and an electrical control system 7.

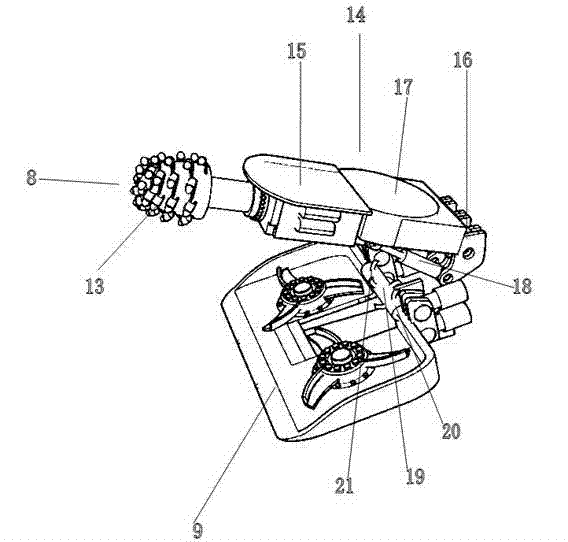

[0025] The excavation system 1 includes a cutting part 8, a shovel part 9, a body part 10, a walking part 11, and a rear support part 12 (see figure 1 ), the system supports the integrated bolter and drives it to dig forward. The walking part 11 is installed under the body part 10 , the rear support part 12 is installed under the rear end of the body part 10 , and the cutting part 8 and the shovel part 9 are installed at the front end of the body part 10 . Wherein the cutting part 8 (see figure 2 ) is located at the front end of the integrated bolter digging machine, while the shovel part 9 is located below the cutting part 8 and connects with the front section of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com