Clamping device used for clamping circular arc-shaped workpiece

A clamping device and arc-shaped technology, which is applied in the field of workpiece clamping and can solve the problem that the clamping jaws cannot fit together.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

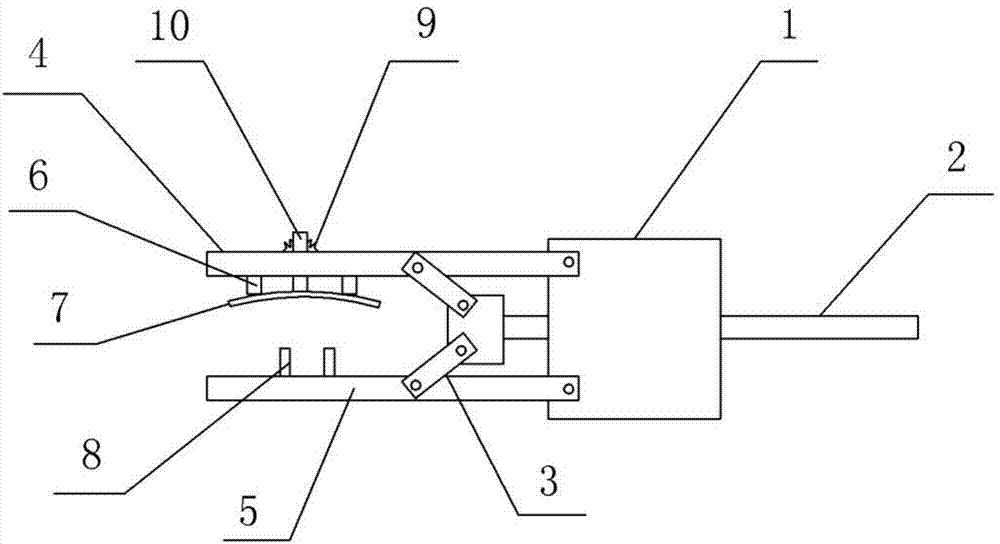

[0013] The reference signs in the drawings of the description include: base 1, control rod 2, drive rod 3, first jaw 4, second jaw 5, limit block 6, elastic piece 7, chuck 8, compression spring 9, slider10.

[0014] like figure 1 As shown, a clamping device for clamping a circular arc-shaped workpiece in this embodiment includes a base 1, a control rod 2, a compression spring 9, two driving rods 3 and two jaws for clamping a workpiece, The two jaws face the workpiece. The control rod 2 is slidably connected to the base 1 , and one end of the two driving rods 3 is respectively connected with the inner sides of the two jaws, and the other ends are connected with the control rod 2 . The two jaws are divided into a first jaw 4 and a second jaw 5 . The first jaw 4 is provided with a limit block 6, an elastic sheet 7 and a slide bar 10, and a through hole is provided on the first jaw 4, and one end of the slide bar 10 passes through the through hole, and the other end is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com