Vacuum regulating device

A technology of vacuum regulation and vacuum chamber, which is applied in the field of matching equipment of pressing device, can solve the problems of pressing quality of soybean hulls, different water content of bean hulls, and fluctuating pressure of vacuum moisture absorption box.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

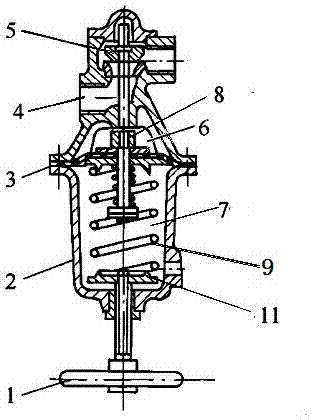

[0013] combined with figure 1 The vacuum regulating device shown includes a housing 2, and a vacuum chamber 4 connected to a vacuum pump is provided in the housing 2, and a regulating valve 5 is provided in the vacuum chamber 4, wherein the housing 2 is also provided with a regulating chamber for regulating There is a film 3 inside the chamber, and the film 3 separates the regulating chamber into a normal pressure chamber 6 and a variable pressure chamber 7. The valve stem passes through the normal pressure chamber 6 and is fixedly connected with the membrane 3 . There is a sealing elastic ring 8 on the outer cover of the valve stem, and the sealing elastic ring 8 is arranged in the normal pressure chamber 6 , and the sealing elastic ring 8 is offset against the wall of the chamber and the film 3 . The housing 2 is threadedly connected with a handwheel 1 , and one end of the screw rod of the handwheel 1 is provided with a baffle 11 . The housing 2 is provided with a rubber t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com