Booster system installed on lng liquid supply pipeline and its control method

A technology of liquid supply pipeline and booster system, applied in charging system, pump control, oil supply device, etc., can solve problems such as difficulty in debugging, inability to meet engine air supply pressure, and increase in gas phase space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

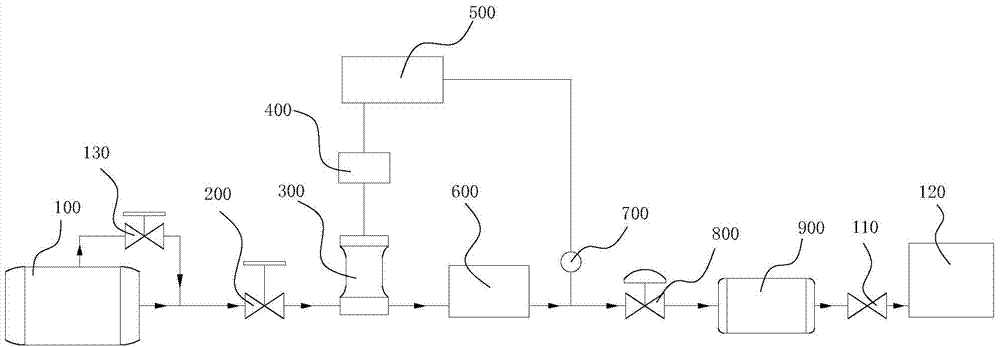

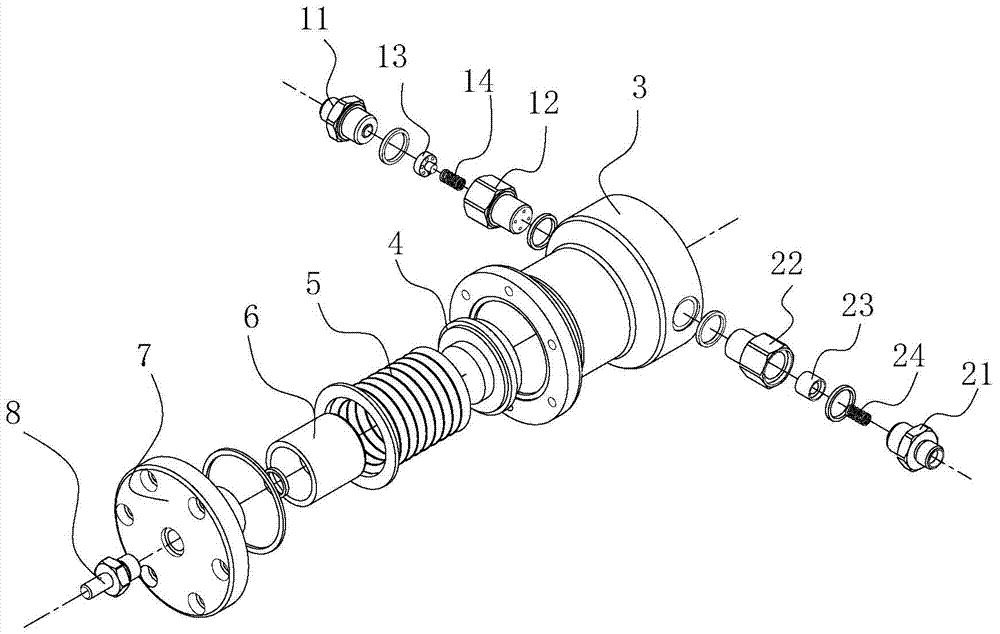

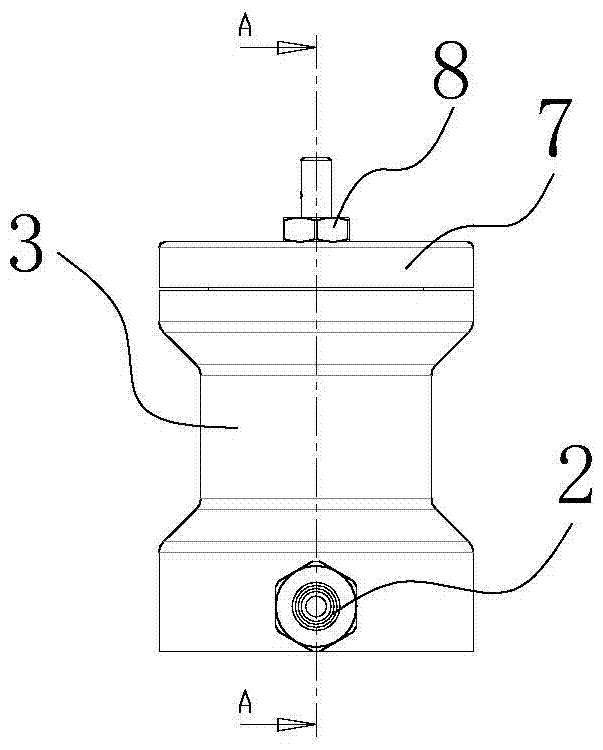

[0029] Example 1: as figure 1 As shown, the pressurization system installed on the LNG liquid supply pipeline, the LNG liquid supply pipeline includes a throttle valve 200, a vaporizer 600, a pressure regulator valve 800, a buffer tank 900 and a stop valve 110; the LNG storage tank 100 is connected to The engine 120 is communicated through the throttle valve 200 , the carburetor 600 , the pressure regulator valve 800 , the buffer tank 900 and the shut-off valve 110 in sequence, that is, the LNG storage tank 100 and the carburetor 600 are communicated through the throttle valve 200 , the carburetor 600 and the buffer tank 900 are communicated through the pressure regulator valve 800, and the shut-off valve 110 is arranged between the buffer tank 900 and the engine 120; the booster system includes a pipeline booster pump 300, the pipeline booster pump driving device 400, the pressure control unit 500 and the pressure sensor 700; the pressure sensor 700 is arranged on the pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com