Piston type internal combustion engine for quickly passing through dead point through magnetic boosting

A piston type, internal combustion engine technology, applied in mechanical equipment, machines/engines, etc., can solve the problems of unstable crankshaft rotation, different, unable to achieve work efficiency, etc., and achieve the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The magnetic-assisted piston internal combustion engine passing through the dead center quickly will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0017] First of all, it should be noted that the present invention only improves part of the structure of the piston internal combustion engine in the prior art, so only the improved part of the structure is described in detail, and the existing structure without improvement is not repeated.

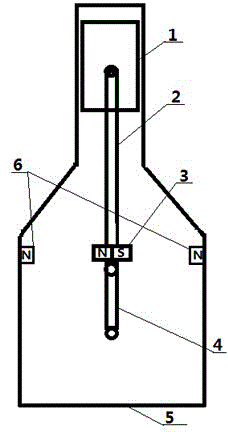

[0018] Such as figure 1 As shown, the structure of the piston-type internal combustion engine that is magnetically assisted to quickly pass through the dead center in this embodiment includes a cylinder 5, a piston 1, a connecting rod 2 and a crank 4, and the above-mentioned structure is no different from the prior art. The improvement is that magnets are respectively arranged on the inner walls of the connecting rod 2 and the cylinder 5, wherein a magnet-3 is provided on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com